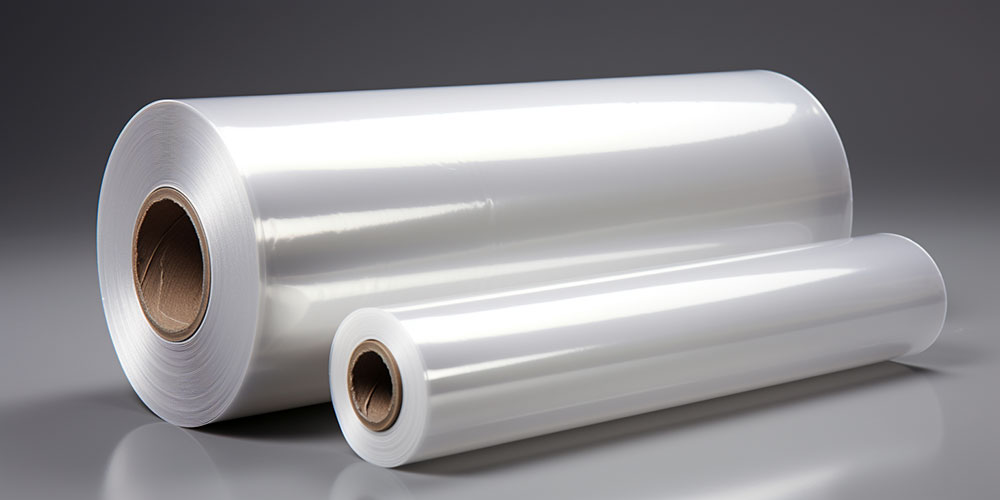

Pallet stretch film is more than just a wrapping tool—it’s a strategic ally in the world of warehousing and inventory management.

In the realm of warehousing and logistics, the twin pillars of efficiency and security stand tall. Given the immense volume of products transitioning through these centers daily, there’s a continuous imperative to guarantee not just proper storage but also protection against potential harm. This is where pallet stretch film steps in—an ostensibly straightforward solution, but crucial in the complex domain of inventory management. In this piece, we will explore the myriad benefits of integrating pallet stretch film into warehousing operations.

Pallet stretch film serves as a shield, separating stored items from external conditions. By enveloping products, it defends them against elements like dust, moisture, and various impurities that might compromise their quality or cause decay, particularly for products vulnerable to environmental influences.

One of the primary purposes of using stretch film is to stabilize and secure palletized goods. By wrapping items tightly, the stretch film helps prevent movement within the pallet, reducing the risk of damage due to shifting during transportation or while in storage.

A pallet wrapped tightly with stretch film can act as a deterrent against pilferage. The wrap makes it more challenging for would-be thieves to access the items without noticeable tampering, offering an additional layer of security.

Compared to other packing materials and methods, stretch film is relatively inexpensive. Additionally, with the invention of automated stretch wrap machines, businesses can further reduce labor costs, allowing for more goods to be wrapped in less time.

Transparent stretch film allows visual inspection of goods without the need to unwrap the pallet. This is especially beneficial for inventory checks and verifications, making the process faster and more efficient. Colored films can also be used to categorize items or denote special handling requirements.

UV Protection

Some stretch films are infused with UV inhibitors. These become crucial for items that may be stored outdoors for prolonged durations, shielding them from the detrimental impacts of the sun’s UV radiation.

With growing environmental concerns, many manufacturers now offer eco-friendly, biodegradable stretch films. These films break down over time, reducing the environmental impact and supporting businesses in their sustainability efforts.

By consolidating products onto pallets and wrapping them securely with stretch film, warehouses can maximize their storage space. A tightly wrapped pallet occupies less space and allows for safer stacking, thus optimizing the warehouse’s storage capacity.

Pallet stretch film is more than just a wrapping tool—it’s a strategic ally in the world of warehousing and inventory management. From protection against environmental hazards to improving efficiency in inventory control, its advantages are numerous and vital for operations of all sizes. As the demands of the logistics and warehousing industry evolve, the role of pallet stretch film remains constant: to safeguard and streamline, ensuring that goods reach their destination in the best possible condition.

© 2024 Crivva. All Rights Reserved.