Working Principle of Eccentric Plug Control Valves: Design, Functionality, and Applications

Understanding Eccentric Plug Control Valves: Design, Function, and Industrial Applications

Introduction

China Control valves are fundamental to industrial fluid systems, managing flow rate, pressure, and direction with precision. Among these, the eccentric plug control valve offers a unique design tailored for challenging media—such as slurries, viscous fluids, and abrasives—making it an optimal solution for tough operating environments.

This article provides a detailed overview of the working principle, features, applications, and performance benefits of eccentric plug control valves in modern industrial processes.

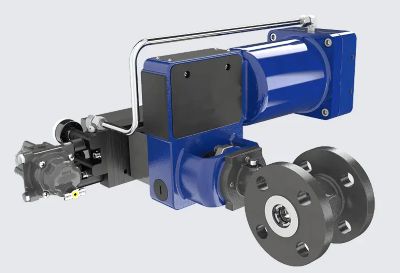

An eccentric plug control valve is a quarter-turn rotary valve designed for precise flow regulation. Unlike traditional plug valves, it uses an off-center (eccentric) plug, which reduces friction, minimizes seat wear, and provides a tight shutoff—ideal for severe service conditions.

Key Design Highlights:

Eccentric Plug Geometry: The offset plug lifts away from the seat during rotation, reducing contact wear and extending service life.

Durable Construction: Built from robust materials like stainless steel or hardened alloys to resist corrosion and abrasion.

Secure Shutoff: Ensures zero leakage with soft seats (Class VI) or minimal leakage with hard seats (Class IV).

Self-Cleaning Action: The rotating plug sweeps away debris, reducing the risk of blockage.

This makes eccentric plug valves highly suitable for sectors such as oil and gas, chemical processing, power generation, and water treatment.

Eccentric plug control valves function through a simple but efficient rotary motion:

The plug rests tightly against the seat, creating a robust seal. The eccentric design distributes sealing pressure evenly, preventing leakage under high-pressure conditions.

As the valve opens, the plug rotates 90 degrees and immediately lifts off the seat, minimizing sliding friction and reducing seat wear.

Flow is modulated by the degree of plug rotation. The straight-through flow path reduces turbulence and pressure loss, ensuring accurate and efficient flow control.

The rotating motion and seat design help prevent particulate accumulation, making these valves ideal for slurry and high-solids media.

| Feature | Benefit |

|---|---|

| Tight Shutoff | Class IV (metal seat) and Class VI (soft seat) options for zero or minimal leakage. |

| Low Operating Torque | Eccentric design reduces friction, requiring less actuation force. |

| Self-Cleaning Mechanism | Reduces maintenance by preventing buildup on the valve seat. |

| Extended Seat Life | Seat protected from direct flow impact, reducing erosion. |

| Split Spool Construction | Allows material customization for body and trim components. |

| One-Piece Stem | Ensures alignment and reliability during operation. |

| Anti-Fly-Out Stem | Enhances safety under high-pressure conditions. |

| Easy Maintenance | Simple assembly and disassembly for reduced downtime. |

Thanks to their durability and accuracy, eccentric plug control valves are widely used in the following industries:

Handles crude oil, refined products, and gas

Suitable for corrosive and high-pressure service

Manages acids, alkalis, and abrasive fluids

Resistant to chemical attack and mechanical wear

Controls feedwater, steam, and condensate

Withstands extreme temperature and pressure conditions

Regulates sludge and slurry flows

Self-cleaning action prevents clogging

| Advantage | Compared to Globe/Ball Valves |

|---|---|

| Higher Flow Capacity | Straight-through path with minimal resistance |

| Longer Service Life | Reduced seat erosion and wear |

| Lower Maintenance | Self-cleaning design prevents buildup |

| Improved Safety | Anti-fly-out stem and tight shutoff design |

To ensure optimal performance and longevity, consider the following:

Use corrosion-resistant alloys (e.g., stainless steel, duplex) for aggressive chemicals.

Opt for wear-resistant materials in abrasive or slurry applications.

Confirm ratings align with your system’s conditions (e.g., ANSI Class or PN rating).

Select the correct size and flow coefficient (Cv) for desired flow rates and control accuracy.

Manual: for basic on/off use

Pneumatic/Electric/Hydraulic: for automated, throttling, or high-cycle operations

Soft-seated for critical shutoff (ANSI Class VI)

Metal-seated for high-temp, abrasive flows

Choose valves with easy disassembly and replaceable parts.

Self-cleaning designs reduce service intervals in dirty media.

Eccentric plug control valves offer a robust, precise, and low-maintenance solution for demanding industrial fluid control applications. Their innovative design provides superior sealing, resistance to wear, and enhanced flow performance, making them ideal for sectors where reliability and operational efficiency are critical.

For engineers, plant managers, and process designers, integrating eccentric plug control valves ensures enhanced system reliability, reduced downtime, and long-term cost savings.Know more about Google SEO Directory