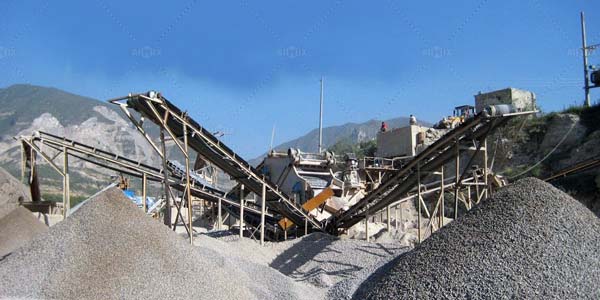

Choosing a stone crusher plant? Look beyond price. Focus on core durability, operational efficiency, and vital manufacturer support for long-term value.

The decision to invest in a stone crusher plant is a significant one, pivotal to the long-term viability and profitability of any quarrying or construction enterprise. While the initial purchase stone crusher plant price naturally commands immediate attention, an overemphasis on this single figure can be a perilous oversight. The true cost of ownership, and indeed the ultimate success of your investment, is woven from a far more intricate tapestry of considerations. Focusing solely on the capital outlay is akin to judging a book by its cover; it ignores the substantive chapters on performance, durability, and operational harmony that lie within. A discerning buyer looks beyond the invoice to understand the intrinsic value and latent potential of the plant, recognizing that the cheapest option upfront can often become the most expensive asset over its lifecycle. True value is found not in a low initial cost, but in a machine’s unwavering reliability, its operational frugality, and the supportive partnership that stands behind it.

Before a single ton of material is processed, the inherent quality of the plant’s design and construction sets the stage for its entire operational lifespan. The robustness of its core components is non-negotiable. Investigate the lineage of the crusher itself—is it a jaw crusher with a formidable crushing chamber and a robust eccentric shaft, or a cone crusher with advanced hydraulic systems for precise setting regulation? The material of wear parts like mantles, concaves, and jaw plates is critical; they should be manufactured from high-grade, abrasion-resistant manganese steel to withstand the relentless punishment of processing hard stone. The structural integrity of the plant’s frame and the supporting conveyors is equally vital, as they must endure constant vibration and heavy loads without succumbing to metal fatigue.

Beyond the crusher’s heart, you must scrutinize the plant’s production capacity and, just as importantly, its product versatility. A plant’s stated capacity is a theoretical maximum under ideal conditions; a more pragmatic assessment involves its performance in your specific context. What is the feed material’s hardness, abrasiveness, and moisture content? More crucially, what final products do your market demands require? The ability to produce a diverse range of aggregate sizes—from base course and sub-base to precisely graded chippings and manufactured sand—is a tremendous commercial advantage. This versatility is often achieved through a well-designed closed-circuit system with a powerful screen that efficiently recirculates oversize material. A stone crusher plant that can be quickly reconfigured to shift production between different product specifications provides a level of operational agility that can capture fleeting market opportunities.

Finally, the plant’s configuration and its adaptability to your specific site must be thoroughly evaluated. Is a stationary plant the right long-term solution, or does your project pipeline demand the mobility of a track-mounted or portable system? Consider the plant’s physical footprint and its logistical requirements. How will it be transported to the site? What are the foundation requirements? A well-conceived plant layout facilitates good material flow, minimizes bottlenecks, and enhances safety by providing clear access for maintenance. The goal is to select a plant that feels less like an external piece of machinery and more like a seamlessly integrated component of your unique operational landscape.

Once the plant is commissioned, its day-to-day performance becomes the primary determinant of its value. Here, the focus shifts from initial cost to the ongoing cost of operation, where efficiency is paramount. The plant’s appetite for fuel or electrical power is a direct and recurring expense. Modern, well-engineered plants incorporate features that optimize energy consumption, such as highly efficient diesel engines or electric drives, and hydraulic systems that provide power on demand rather than running constantly. An energy-profligate plant will silently erode your profit margins with every hour it operates. The cumulative savings from even a modest improvement in fuel efficiency can, over thousands of operational hours, completely overshadow a slightly higher initial purchase price.

The plant’s design also dictates its maintenance regimen, which directly impacts both downtime and long-term longevity. Seek out designs that prioritize serviceability. Are lubrication points easily accessible? Can wear parts be replaced without complex and time-consuming disassembly? For instance, a jaw crusher that features a hydraulic toggle relief system not only protects the crusher from tramp metal but can also simplify setting changes. The availability of spare parts is the other side of this coin. A crusher may be brilliantly designed, but if critical spare parts are exorbitantly expensive or have lead times measured in months, a single breakdown can bring your entire operation to a standstill. Establishing a reliable channel for genuine, competitively priced spare parts is an operational necessity, not an afterthought.

Perhaps the most underappreciated aspect of modern crushing plants is the sophistication of the control system. This is the nerve center of the entire operation. A well-designed control system does more than just start and stop motors; it provides the operator with real-time data on production rates, power draw, and crusher settings. It can automate sequences, monitor for faults, and provide diagnostic information to preempt failures. This elevates the operation from a manual, labor-intensive process to a finely tuned production line. An intuitive control system reduces the scope for operator error, enhances safety, and ensures the plant is consistently operating at its peak efficiency, delivering the highest quality product with minimal waste.

A stone crusher plant is a long-term investment, and no piece of heavy machinery is immune to the need for occasional support. This is where the transaction evolves from a simple purchase into a relationship, and the character of your supplier becomes critically important. The warranty offered is your first indicator of the manufacturer’s confidence in their product. Scrutinize its terms, duration, and what components are covered. A comprehensive warranty is a form of risk mitigation for your business.

However, a warranty is only as good as the service that backs it. Investigate the supplier’s commitment to after-sales support. Do they have a dedicated team of technical specialists who can provide remote assistance or, if necessary, dispatch to your site? The value of a service engineer who can diagnose a complex hydraulic issue over the phone or guide your local mechanic through a repair procedure is immeasurable. This support network is a vital asset that protects your investment from prolonged and costly downtime. The supplier should act as an extension of your own team, demonstrating a vested interest in your plant’s continued productivity.

Therefore, the supplier’s reputation and industry pedigree are not merely abstract qualities; they are tangible indicators of future support. A company with a long-standing presence and a portfolio of successful installations has a reputation to uphold. They are more likely to be in business a decade from now, ensuring you can still source parts and receive support. Look for testimonials and case studies, and if possible, speak to other plant owners who have experience with the brand. Choose a supplier that demonstrates a collaborative approach, one that seeks to understand your business objectives and offers solutions tailored to achieve them. In the final analysis, the right stone crusher plant is not just a machine you buy; it is a partnership you enter, a foundational decision that will influence the productivity and prosperity of your enterprise for years to come.