Silicon Valley’s blog on the introduction of steel fabrication drawings. do visit our website to get more information about our services.

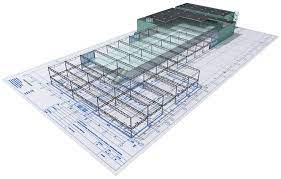

In the world of construction and engineering, precision and accuracy are paramount. Steel fabrication drawings are instrumental in achieving these goals, as the blueprint for creating steel structures and components. These drawings are detailed, scaled diagrams that provide all the necessary information for fabricators and welders to manufacture steel parts accurately. Let’s delve deeper into the significance, components, and creation process of steel fabrication drawings.

Precision:

Steel fabrication drawings are meticulous representations of each component of a steel structure. They include exact measurements, dimensions, and specifications, ensuring that every part fits perfectly during assembly. Accurate drawings minimize the risk of errors, discrepancies, and adjustments during the fabrication and erection phases, thereby maintaining the integrity of the construction project.

Communication:

A steel fabrication drawing acts as a universal language between different stakeholders in a project, including engineers, architects, fabricators, and contractors. By providing unambiguous and standardized information, these drawings ensure that everyone involved understands the design requirements and construction methods. This clarity prevents miscommunication and streamlines the workflow, making each stage of the project more efficient.

Cost-Efficiency:

Time is money in the construction industry. Inaccuracies in design can lead to costly rework, project delays, and wastage of materials. Steel fabrication drawings mitigate these risks by delivering comprehensive details upfront. This foresight allows for better planning, procurement of the right materials in the correct quantities, and smooth fabrication processes, ultimately saving time and reducing costs.

Safety:

Safety is a top priority in any construction project. Steel fabrication drawings contribute significantly to the safety of workers and the structural integrity of the final product. These drawings specify details like welding procedures, material types, and load-bearing capacities. By adhering to these specifications, fabricators ensure that the structure can withstand the intended loads and environmental conditions, ensuring its stability and durability.

Plan Views:

The plan view is a top-down representation of the steel structure. It shows the layout, position, and orientation of beams, columns, and other structural elements. This view helps fabricators understand how different components fit together in a horizontal plane.

Elevations:

Elevation drawings provide a vertical perspective of the structure, offering insights into the height and arrangement of various components. They show how columns, beams, and other elements stack up and connect from the ground up. Elevations are crucial for understanding how the structure appears from different sides and how it integrates with other architectural elements.

Sections:

Sections are cut-through views of the structure, showing an imaginary slice through specific parts. These drawings reveal internal features that are not visible in plan or elevation views. Sections are essential for detailing the internal composition of connections, beams, and braces. They provide a clear understanding of how different elements interact within the structure.

Details:

Detailed drawings focus on specific, often complex, parts of the structure. They provide close-up views of critical connections, joints, and components. These details include precise measurements, welding symbols, bolt sizes, and other specifications needed for accurate fabrication and assembly. Detailed drawings ensure that every minor aspect is accounted for and executed correctly.

Design Stage:

The design stage involves creating the conceptual layout of the steel structure based on the project requirements. Engineers and architects collaborate to develop a design that meets functional, aesthetic, and safety criteria. They consider factors like load-bearing capacity, environmental conditions, and architectural constraints. The result is a preliminary design that serves as the foundation for detailed documentation.

Drafting:

Using specialized software like AutoCAD, Tekla Structures, or Revit, drafters convert the conceptual design into detailed fabrication drawings. This involves creating accurate representations of each component, complete with dimensions, material specifications, and assembly instructions. Drafters ensure that the drawings conform to industry standards and reflect the engineer’s design intent.

Review:

Once the draft drawings are ready, they undergo a thorough review process. Engineers, architects, and sometimes even fabricators examine the drawings for accuracy, feasibility, and compliance with industry norms. They check for any potential issues, such as clashes, misalignments, or design inconsistencies. This collaborative review helps identify and resolve problems before fabrication begins, ensuring a smoother construction process.

Fabrication:

With the approved drawings in hand, fabricators commence the actual production of steel components. They follow the drawings meticulously, cutting, welding, and assembling parts as specified. The detailed information in the drawings guides every step of the process, from material selection to final assembly.