ZDigitizing is offering a wide range of digitizing solutions to meet the needs of businesses and individuals alike. With expertise in logo digitizing.

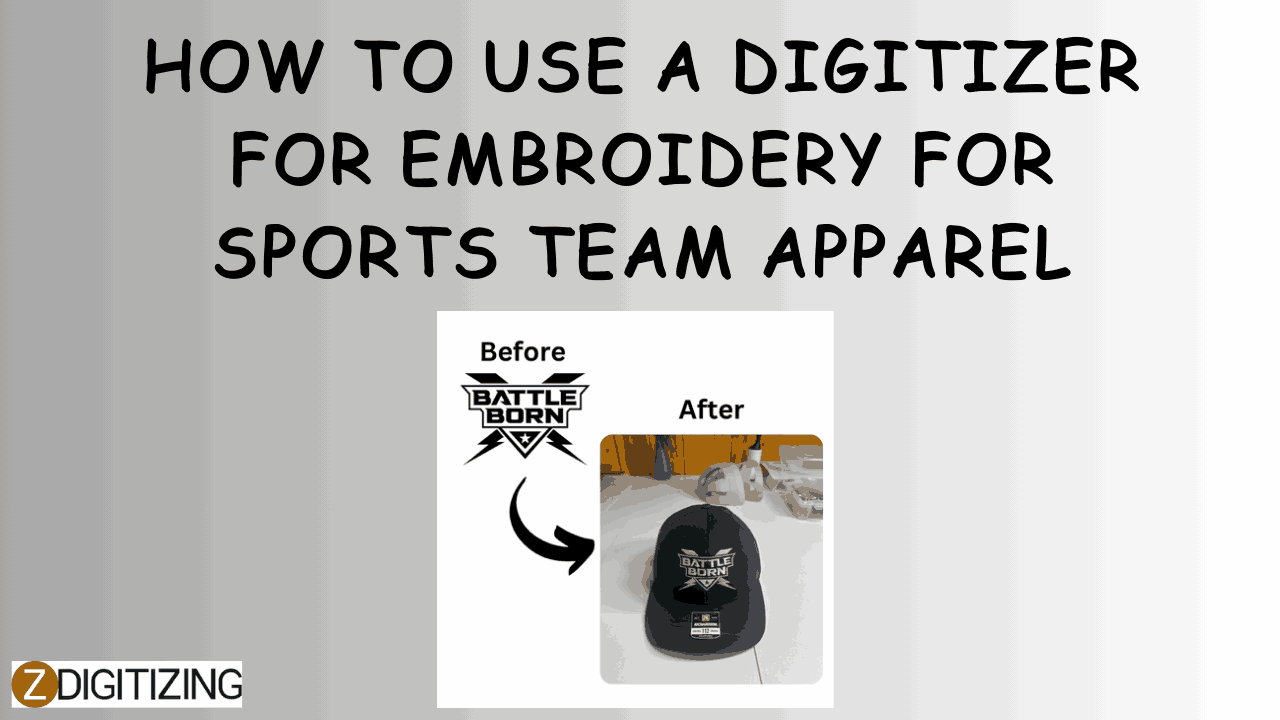

Sports team apparel—jerseys, caps, or jackets—demands bold, durable embroidery that showcases team pride. Logos, names, and numbers need to stand out, withstand wear, and look sharp on stretchy or textured fabrics. A digitizer for embroidery, whether software or a skilled process, is your tool to create these standout designs with precision. How do you use a digitizer for embroidery for sports team apparel? This guide walks you through the steps, from designing bold logos to stitching on tricky materials, ensuring your team gear scores big. Let’s get your squad ready to shine.

Sports gear isn’t just clothing—it’s a statement. Fabrics like polyester knits or twill are stretchy, thick, or textured, and designs must be tough yet flexible. Using a digitizer for embroidery ensures logos pop, names stay legible, and stitches hold up through games and washes—here’s how to make it happen.

To embroider sports apparel, gather these essentials:

Team logos need to be eye-catching and adaptable—small for caps, large for jackets—without losing clarity.

Preview at 200% zoom—ensure details hold across sizes.

Sports apparel takes a beating—stitch types must balance durability with flexibility for stretchy fabrics.

Use satin for names—keeps them legible and tough.

Polyester knits stretch, twill is thick—settings must adapt to avoid puckering or sinking.

Test density—0.6mm suits jerseys, 0.4mm lifts on caps.

A digitizer for embroidery shines when paired with stabilizers—sports fabrics need firm support to handle bold designs.

Hoop tight—cut-away for jerseys, tear-away for caps—keeps stitches steady.

Sports team apparel isn’t just functional—it’s identity. Embroidery must endure sweat, stretches, and cheers while looking sharp. A digitizer for embroidery ensures designs meet these demands—logos that pop, names that last, and stitches that flex. In 2025, with tools like Wilcom or free Ink/Stitch, team gear is easier to perfect—uniting style and strength for every player.

Mastering how to use a digitizer for embroidery for sports team apparel is about teamwork—design, stitches, and fabric syncing for victory. These five steps—crafting bold logos, choosing durable stitches, adjusting settings, stabilizing fabrics, and testing—equip you to create winning gear. Grab your software, pick a team design, and start digitizing. From jerseys to caps, your embroidery will rally the crowd—tough, vibrant, and team-ready!