The Right Way to Integrate Rebar Detailing in BIM – Most Engineers Get This Wrong

Rebar detailing isn’t just about placing steel bars in a 3D model. It’s about connecting structural intent with real-world constructability. Yet, even today, many structural engineers, modelers, and contractors handle rebar detailing as an isolated task. The result? Delayed approvals, field errors, and rework that drain time and money.

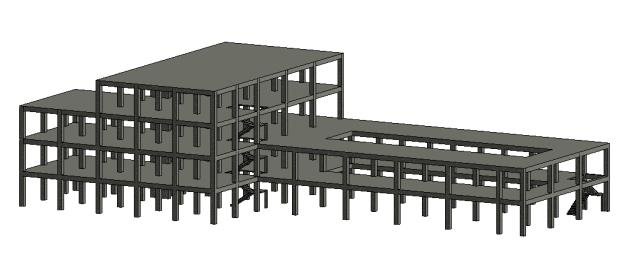

Integrating rebar detailing into Building Information Modelling is no longer optional. It is a necessity in Structural BIM Services. But the process is not as straightforward as importing schedules or referencing 2D details. This blog outlines the correct way professionals should integrate rebar detailing in Structural BIM Modeling Services. Most get it wrong, and the consequences are costly.

One of the biggest mistakes engineers make is treating rebar as secondary in the structural model. Often, the focus is on concrete volumes, wall thicknesses, and beam placements, while rebar is tagged on at the end. This disconnect leads to structural conflicts and shop drawing errors.

Rebar must be treated as a core element of Structural Models from the very beginning. That means:

By doing this, Structural Engineering teams reduce the chances of coordination issues between formwork and steel placement. Contractors benefit from a clearer picture of what needs to be built, resulting in fewer RFIs and less confusion.

Many engineers still believe that rebar detailing can wait until after the main Structural BIM Modeling Services are completed. Their logic is to finalize the structure first and then add reinforcement. But this approach delays coordination and introduces risk.

The correct approach is early integration with dedicated Structural BIM Services. Here is what that involves:

This process helps uncover real constructability issues, such as congestion in beam-column joints or inaccessible rebar placements, long before they reach the construction site. With proper clash detection applied at the detailing level, engineers can move forward confidently with shop drawings, bar bending schedules, and field instructions.

Bar Bending Schedules (BBS) are critical. However, they often remain disconnected from the 3D model, leading to inconsistencies between what is modeled and what is fabricated.

Professionals using advanced Structural BIM Modeling Services link BBS directly to the rebar geometry in the BIM model. This enables:

When properly integrated, BBS becomes more than just a document. It becomes a dynamic output of the model. This level of automation distinguishes high-performing structural BIM teams from those stuck resolving rebar conflicts onsite.

Many teams use BIM solely for modeling while relying on separate software for structural calculations. This is where the disconnect begins. Rebar ends up modeled based on assumptions, not on actual design loads.

To solve this, engineers should adopt a two-way workflow where rebar detailing directly reflects the structural engineering design. Tools like Revit Extensions, SOFiSTiK, and Graitec facilitate this by pulling design data into the modeling environment.

This results in:

Most professionals overlook this workflow due to its complexity. But the improvements in coordination, model quality, and construction performance make it worthwhile.

There is a right way to integrate rebar in BIM, and it starts with changing the mindset that reinforcement comes after the structure.

Most engineers get this wrong by treating rebar as a secondary task. But for those who get it right, the workflow becomes smoother, coordination improves, and construction becomes significantly more predictable.

Start integrating rebar detailing correctly. Because in modern Building Information Modeling, every bar truly counts.