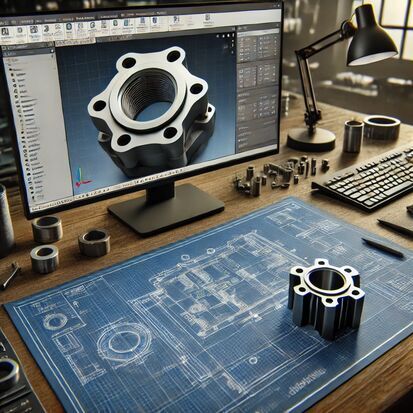

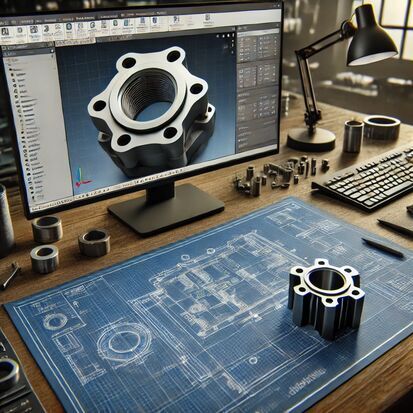

Understanding SolidWorks Detailing Services

How Accuracy in Engineering Projects Is Improved by Advanced Solidworks 3D Modeling and Detailing

© 2024 Crivva - Business Promotion. All rights reserved.