As technology continues to evolve, the injection molding industry is well-positioned to lead in sustainable manufacturing.

Plastic injection molding has long been a cornerstone of modern manufacturing, providing a reliable, cost-effective method for producing high-quality plastic components. However, with growing environmental concerns, the industry faces increasing pressure to reduce its ecological footprint. Traditional injection molding processes often consume significant amounts of energy and raw materials, while generating waste and emissions that can harm the environment. As a result, innovations in plastic injection molding tech are increasingly focused on sustainability, seeking ways to make production greener without sacrificing efficiency or product quality.

Sustainability in manufacturing is not merely a trend but a necessity. Industries are being held accountable for their environmental impact, prompting manufacturers to rethink production methods. In plastic injection molding, sustainable solutions involve not only optimizing machinery and processes but also exploring eco-friendly materials, reducing energy consumption, and implementing recycling programs. By integrating these strategies, businesses can achieve environmentally responsible production while maintaining the speed and precision that have made plastic injection molding tech a global standard in manufacturing.

One of the most significant developments in sustainable plastic injection molding tech is the use of eco-friendly materials. Traditional plastics are typically derived from petroleum-based sources, which are non-renewable and contribute to environmental pollution. In response, manufacturers are increasingly turning to biodegradable plastics, bio-based polymers, and recycled materials. Biodegradable plastics, such as polylactic acid (PLA), can break down naturally over time, reducing long-term environmental impact. Similarly, bio-based polymers derived from renewable resources like cornstarch or sugarcane offer a more sustainable alternative to conventional plastics without compromising performance.

Recycled materials also play a crucial role in reducing waste in plastic injection molding. Post-consumer and post-industrial plastics can be reprocessed and reintegrated into new products, minimizing the need for virgin materials. Advanced plastic injection molding tech enables the processing of recycled plastics without affecting product quality or durability. By adopting these materials, manufacturers not only contribute to a circular economy but also enhance their brand’s commitment to sustainability, appealing to environmentally conscious consumers who prioritize eco-friendly products.

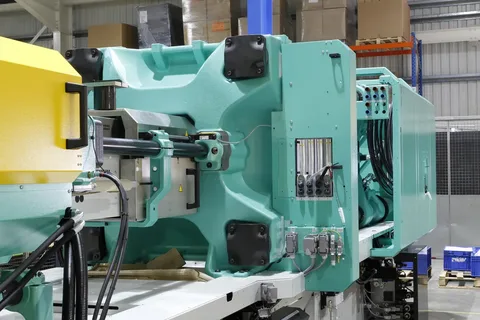

Energy consumption is a major concern in plastic injection molding, as traditional machines can consume vast amounts of electricity during operation. Sustainable plastic injection molding tech addresses this challenge through energy-efficient machinery and optimized production processes. Modern injection molding machines often incorporate servo-electric drives, which consume less energy compared to conventional hydraulic systems. These drives adjust power usage dynamically based on operational demand, significantly reducing electricity consumption and lowering operational costs for manufacturers.

In addition to energy-efficient machinery, process optimization is vital for reducing energy waste. Techniques such as cycle time reduction, precise temperature control, and optimized mold design can decrease the energy required for each production run. Simulation software and advanced monitoring systems allow engineers to analyze and refine production parameters, ensuring that energy is used as efficiently as possible. By prioritizing energy efficiency, manufacturers can achieve significant sustainability gains without compromising the speed, accuracy, or quality associated with modern plastic injection molding tech.

Waste reduction is another critical focus area for sustainable plastic injection molding tech. In conventional injection molding, material scrap from runners, sprues, and defective parts can contribute to significant waste, increasing both environmental impact and production costs. Advanced molding techniques, such as hot runner systems, minimize material waste by keeping plastic molten in the system until it is injected, reducing the volume of discarded material. Similarly, precision mold design and automated quality control help prevent defects, further minimizing waste generated during production.

Process optimization also extends to the efficient use of materials and resources. By integrating digital twin technology and real-time monitoring, manufacturers can predict potential defects, adjust parameters on the fly, and avoid unnecessary material usage. This approach not only conserves resources but also streamlines production, making sustainable practices compatible with high-volume manufacturing. Reducing waste in this manner demonstrates how plastic injection molding tech can evolve into a more environmentally responsible process while maintaining cost-effectiveness and production speed.

Recycling and circular economy strategies are transforming the landscape of sustainable plastic injection molding tech. In a circular economy, materials are reused, refurbished, or recycled rather than discarded, creating a closed-loop system that minimizes environmental impact. Manufacturers are increasingly adopting take-back programs, where end-of-life plastic components are collected, reprocessed, and reintroduced into production cycles. This approach reduces reliance on virgin materials and lowers the overall ecological footprint of manufacturing operations.

Closed-loop recycling systems are particularly effective when combined with advanced injection molding technologies. Modern machines are capable of processing recycled plastics without compromising quality, allowing manufacturers to produce high-performance components from previously used materials. Additionally, innovations in additive manufacturing and multi-material molding enable the creation of products that are easier to disassemble and recycle. By embracing these strategies, companies can align their operations with global sustainability goals while leveraging the capabilities of cutting-edge plastic injection molding tech to maintain efficiency and product quality.

Looking forward, the future of sustainable plastic injection molding tech is likely to be shaped by continued innovation in materials, machinery, and processes. Emerging technologies such as biodegradable composites, energy-recovery systems, and AI-driven production optimization are poised to make injection molding even greener. Researchers are exploring the potential of renewable feedstocks, advanced catalysts, and nanomaterials to produce plastics that are not only eco-friendly but also stronger and lighter than traditional alternatives. These advancements promise to enhance both the environmental performance and functional capabilities of molded products.

In addition, sustainability will increasingly drive industry standards and regulatory frameworks. Governments and industry bodies are setting stricter environmental targets, pushing manufacturers to adopt greener practices. Companies that embrace sustainable plastic injection molding tech will gain a competitive edge, appealing to environmentally conscious consumers and meeting evolving regulatory requirements. By investing in innovation, energy efficiency, and recycling initiatives, the injection molding industry can continue to thrive while playing a vital role in the global effort to protect the environment.

Sustainability in plastic injection molding is no longer optional—it is a critical imperative for manufacturers, consumers, and the planet. By integrating eco-friendly materials, energy-efficient machinery, waste-reducing processes, and circular economy initiatives, the industry can significantly reduce its environmental impact. Advances in plastic injection molding tech make it possible to maintain production speed, precision, and quality while embracing environmentally responsible practices.

As technology continues to evolve, the injection molding industry is well-positioned to lead in sustainable manufacturing. Companies that prioritize green solutions will not only benefit from operational efficiencies and reduced costs but also strengthen their brand reputation and contribute to a healthier planet. Sustainable plastic injection molding tech represents a forward-looking approach that balances economic growth with environmental stewardship, demonstrating that innovation and sustainability can go hand in hand.