In this blog, we dive into the essential practices and standards of steel detailing, shedding light on what makes it an indispensable part of modern architecture and construction.

What is Steel Detailing?

At its core, steel detailing is the process of creating detailed drawings and models of steel structures. These drawings include dimensions, materials, fabrication methods, and other specifications necessary for the construction and erection of steel components. Steel detailers serve as the communication bridge between architects, engineers, and fabricators, ensuring that everyone is on the same page.

Practices in Steel Detailing

1. Use of Advanced Technology

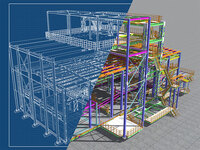

The steel detailing industry has seen substantial advancements in technology, most notably through Building Information Modeling (BIM). BIM allows detailers to create 3D models that provide a visual representation of the entire structure. This technology not only enhances accuracy but also allows for better visualization of how different components interact. From clash detection to enhanced collaboration, BIM is reshaping how steel detailing services are practiced.

2. Collaborative Approach

Collaboration stands at the heart of successful steel detailing. Today’s projects often involve a myriad of stakeholders, including architects, structural engineers, and contractors. A clear line of communication between these parties ensures that any potential discrepancies are identified and resolved early in the project. Regular meetings, feedback sessions, and updates during the detailing process can significantly contribute to a smooth workflow.

3. Adherence to Industry Standards

Steel detailing must comply with strict industry standards set forth by organizations like the American Institute of Steel Construction (AISC) and the American Welding Society (AWS). These standards ensure that the detailing processes meet safety and quality requirements. Detailers must continually update their knowledge based on revisions to these standards, ensuring their practices remain compliant and reliable.

4. Quality Assurance Practices

Quality assurance is an integral part of steel detailing practices. It involves meticulous checks at various stages of the detailing process to catch potential errors before they become critical issues. Techniques like peer reviews, checklists, and the use of specialized software tools help detailers ensure that their work is accurate and aligned with project specifications.

5. Continuous Learning and Adaptation

The construction industry is dynamic, with emerging technologies and evolving practices. Steel detailers must commit to continuous learning to stay abreast of new tools, software, and methodologies. Attending workshops, participating in professional organizations, and accessing online courses are vital for skill enhancement and professional growth.

Standards in Steel Detailing

1. AISC Detailing Standards

The AISC provides a set of standards specifically for steel detailing known as the “AISC Code of Standard Practice.” This code outlines the roles and responsibilities of detailers, fabricators, and contractors, ensuring that everyone involved in a project understands their duties. Adhering to these standards helps establish a common language and set expectations across the board.

2. NISD Standards

The National Institute of Steel Detailing (NISD) also plays a pivotal role in establishing detailing standards. They provide guidelines that address the comprehensive needs of the detailing profession, from educational resources to ethical practices. The NISD’s involvement ensures that steel detailers are equipped with the best practices for their craft.

3. Level of Detail (LOD)

Level of Detail (LOD) is a critical concept in steel detailing that defines the amount of detail provided in a given model or drawing. Different projects may require varying levels of detail depending on their complexity and requirements. Understanding the LOD ensures that details align with the project’s expectations and facilitates proper collaboration among stakeholders.

4. Coding and Annotation Standards

Proper coding and annotation in detailing are essential to ensure clarity in communication. Standardized codes for materials, types of connections, and fabrication processes reduce misunderstandings and streamline the workflow. These annotations serve as vital references for fabricators and construction teams, ensuring everyone is well-informed.

Steel detailing services are a cornerstone of modern construction, ensuring that steel structures are designed, fabricated, and erected with the utmost precision. By embracing advanced technologies, fostering collaboration, adhering to industry standards, and instilling quality assurance practices, detailers can meet the evolving demands of the construction industry. As projects become more complex and technology continues to advance, the role of steel detailing will only grow in importance, making it an essential service for successful construction endeavors. Whether you’re a contractor, architect, or fabricator, understanding and valuing the practices and standards of steel detailing can lead to a more successful project outcome and a stronger built environment.