Discover practical ways to cut mistakes in U.S. building projects. From planning to coordination, learn how to save time and money.

Starting a building project is exciting, but let’s be real—it’s also nerve-wracking. Between tight budgets, deadlines, and multiple teams working at once, mistakes can creep in fast. One wrong measurement or a missed detail, and suddenly you’re staring at delays, rising costs, or worse, a safety risk.

In the U.S., construction projects often juggle strict codes, different trades, and constant pressure to move quickly. That’s why preventing errors isn’t just helpful—it’s crucial. The good news? With a few smart steps, you can cut down mistakes, save money, and keep things running smoothly.

A successful project starts with clear plans. If the drawings are confusing or missing details, problems will show up later. Research even points out that poor planning causes nearly half of all building errors.

But it’s not just about drawings. Communication is everything. Hold proper kickoff meetings. Make sure everyone knows what’s expected. Share updates often. When architects, engineers, and contractors understand not just what to do but why, mistakes shrink dramatically.

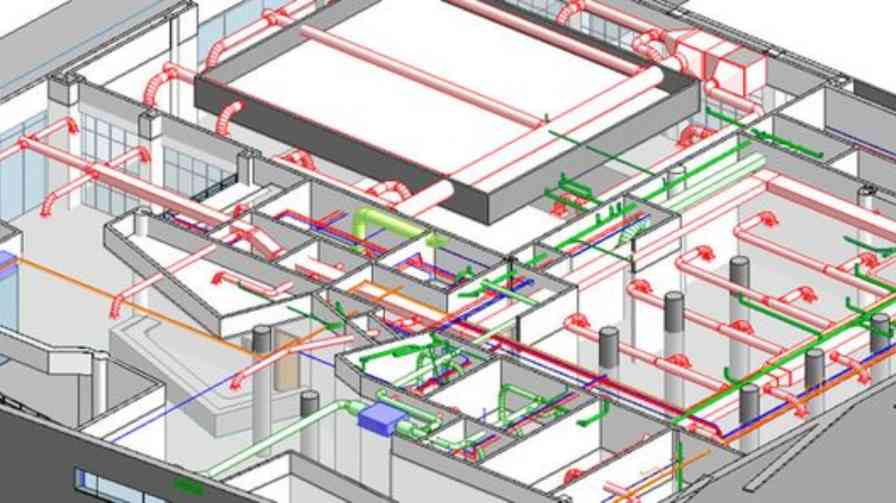

Construction isn’t just blueprints anymore. Digital tools now let you spot issues before a single wall goes up. Building Information Modeling (BIM) is one of the best examples. It creates a 3D view of how systems—like HVAC, plumbing, and wiring—actually fit together.

This way, if a duct clashes with a beam or pipes cross electrical lines, you’ll see it before the work starts. Catching those conflicts early can save thousands of dollars and weeks of wasted time.

When plans are off, the whole project wobbles. That’s where mep drafting services step in. They give you clean, detailed layouts for mechanical, electrical, and plumbing systems. In the U.S., where codes vary from state to state, accurate drafting isn’t just nice—it’s essential.

Contractors need drawings they can trust. If designs match what’s happening on site, collaboration is smoother, mistakes drop, and everyone’s life gets easier. One strong set of drawings can save countless hours of confusion later.

Even with perfect plans, construction sites can be messy. Deliveries arrive late. Weather slows crews. Materials don’t always fit as expected. That’s why site inspections matter so much.

Walking the site regularly helps catch small errors before they grow into big ones. A misplaced wall or an off-center conduit might not sound major, but fixing it later can mean tearing things apart. Frequent checks keep the project aligned with both plans and quality standards.

Construction mistakes often come down to human error. The good news? Training reduces that risk. Well-trained workers know how to read plans, follow codes, and recognize when something feels wrong.

Experience also matters. Veteran supervisors have seen enough jobs to spot red flags early. Pairing newer workers with seasoned ones spreads that knowledge across the team. It’s not just about doing the job—it’s about doing it right the first time.

Deadlines are a constant reality. Everyone wants projects done yesterday. But moving too fast often leads to errors that cost far more time in the long run.

Think of it this way: installing a wall in the wrong place takes hours. Fixing it later might take days. Balancing speed with accuracy means your team stays efficient without losing focus on quality.

Every project brings together electricians, plumbers, HVAC crews, and more. If they don’t coordinate, chaos follows. A classic example? A plumbing line gets laid where electrical was supposed to go.

This is exactly why mep coordination services exist. They make sure every trade knows what the others are doing, reducing on-site conflicts. When everyone works from the same plan, delays shrink and rework costs disappear.

Sometimes mistakes happen because workers are rushing under unsafe conditions. When crews don’t feel safe, attention to detail drops.

Keeping sites safe isn’t just about avoiding accidents. It also helps workers focus on the task. Following OSHA rules, enforcing protective gear, and creating a secure environment pays off with better quality work and fewer mistakes.

Every project teaches something. Maybe a certain supplier kept causing delays. Maybe a process didn’t work well. Collecting these lessons helps the next project go smoother.

Many U.S. firms run “post-mortem” meetings once a job finishes. Teams discuss what went right and what went wrong. It’s a simple habit that builds a long-term culture of improvement.

No two places in the U.S. are the same. Different regions have different codes, climates, and regulations. That’s why local expertise is gold.

Working with regional consultants can catch details outsiders might miss—like specific fire safety rules or zoning quirks. Local knowledge keeps projects compliant and moving forward.

For example, strand consulting corporation has built a strong reputation for helping contractors handle local compliance. Partnerships like this reduce risk while adding peace of mind.

Cutting errors in building projects isn’t about perfection. It’s about planning smart, using the right tools, and building strong teams. From accurate drafting to regular inspections, every step counts.

The U.S. construction world is already full of challenges. Adding avoidable mistakes doesn’t help anyone. But by focusing on technology, training, and local expertise, you can finish projects on time, within budget, and with far fewer setbacks.

At the end of the day, building right the first time isn’t just efficient. It builds trust.

1. Why do small errors matter so much in construction?

Even tiny mistakes can snowball into big problems. A wrong measurement or overlooked detail can delay the project and raise costs.

2. How can technology reduce mistakes on job sites?

Tools like digital drafting, drones, and project management software keep everything accurate and organized, making errors less likely.

3. What’s the role of training in avoiding construction errors?

Well-trained teams know what to look for and how to prevent mistakes before they happen. Knowledge saves time and money.

4. Why is local expertise important in construction projects?

Local pros understand codes, materials, and regional challenges. Their insight helps projects move smoothly without costly surprises.

5. How can construction teams build trust with clients?

By delivering quality work the first time, sticking to deadlines, and avoiding unnecessary errors, trust naturally grows.