Understanding rebar types is key for accurate detailing, ensuring structural safety, precision, and efficiency in every construction project.

Hi! Today, let’s talk about something very important but often overlooked in construction—Rebar and its significance in detailing. It’s easy to think of rebar as just another element in the concrete mix, but in reality, it plays a critical role in ensuring that structures remain strong, stable, and safe. Whether you’re a contractor, engineer, or project manager, understanding the different types of rebar and their impact on detailing can make a huge difference.

Why does this matter? Knowing rebar types helps you avoid costly mistakes, prevents material wastage, and speeds up the construction process. This article will explain the types of rebar, why they matter in detailing, and how choosing the right one can save time and money.

Rebar, short for reinforcing bar, is a steel bar used to strengthen concrete. Concrete works well under compression but poorly under tension. Rebar compensates for this weakness by increasing tensile strength. In other words, rebar acts like the spine of a building.

From basic rebar shop drawings to advanced column rebar detailing, understanding how rebar works and its properties is essential to structural safety and project success.

Characteristics: Soft, flexible, and easy to bend.

When Used: Low-rise buildings and residential projects.

Impact on Detailing: Easy to handle but poor in corrosion resistance, requiring attention in moist environments.

Characteristics: Stronger and stiffer than mild steel.

When Used: High-rises, bridges, and commercial structures.

Impact on Detailing: Requires precision in placement since bending is harder. Tekla rebar detailing is often preferred.

Characteristics: Hard outer surface with a flexible core.

When Used: Earthquake-prone and high-stress areas.

Impact on Detailing: Needs attention to balance flexibility and strength.

Characteristics: Highly corrosion-resistant but costly.

When Used: Marine and coastal structures, chemical plants.

Impact on Detailing: Requires specialized tools for bending and cutting.

Characteristics: Steel coated with epoxy for corrosion resistance.

When Used: Bridges, highways, and parking structures.

Impact on Detailing: Coating can be damaged easily; careful handling is required.

Characteristics: Protected with a zinc coating.

When Used: Medium-moisture or chemical environments.

Impact on Detailing: Needs careful placement to avoid damaging the coating.

Mild steel bends easily but is weaker. High-tensile and TMT bars provide strength but demand precise spacing and placement.

In harsh environments, stainless, epoxy-coated, or galvanized rebars must be detailed with care to avoid damaging protective layers.

Mild steel is easy to bend, but high-tensile steel requires accurate planning. Advanced tools like Tekla rebar detailing software enhance efficiency and reduce errors.

Precision in Measurements: Stronger rebars require tighter detailing tolerances.

Spacing and Placement: Stronger rebars often mean fewer bars but require exact placement.

Complexity of Detailing: Stainless steel and TMT rebar add complexity due to coatings and hardness.

Avoiding Misplacement: Proper detailing prevents weak points in structures.

Minimizing Wastage: Correct selection ensures the right amount of rebar is used.

Ensuring Safety: Detailing ensures long-term stability and reliability.

Timeline: Harder rebar, like HYSD, takes longer to cut, bend, and install.

Cost: Stainless and epoxy-coated rebars are expensive but reduce maintenance. Outsourcing rebar detailing helps balance quality and cost.

Professional detailers adapt designs according to the type of rebar.

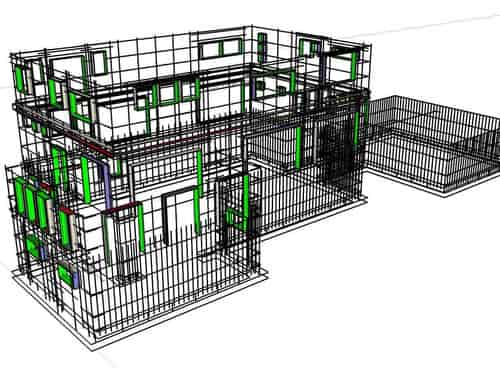

Specialized Services: Tools like BIM and Tekla ensure accurate detailing.

Technology: 3D models minimize errors and ensure precision in complex projects.

Factors to Consider: Strength requirements, environmental conditions, and budget.

Collaboration: Engineers and contractors should work together to make informed choices.

Rebar is not just steel embedded in concrete—it is the backbone of structural safety. Different rebar types affect strength, flexibility, corrosion resistance, cost, and project timelines. By understanding these differences, you can reduce mistakes, improve efficiency, and ensure integrity.

Whether you’re detailing with mild steel, TMT, stainless, or epoxy-coated rebar, precision and proper planning are key. Professional rebar detailing services, supported by advanced tools like Tekla and AutoCAD, help make the most of each rebar type.

In the end, selecting the right rebar and detailing it correctly ensures durability, savings, and long-term safety. The right choice today builds stronger, safer, and smarter structures for tomorrow.