Plastic pollution has reached alarming levels. This growing crisis calls for innovative and effective pyrolysis solutions.

Plastic has become an integral part of our daily lives. From the packaging of our groceries to the disposable items we use, plastic is everywhere. However, its convenience comes at a high cost. Most plastics are non – biodegradable, meaning they persist in the environment for hundreds of years. As they break down, they form smaller and smaller particles known as microplastics.

These microplastics have found their way into our food chain. We consume them when we eat seafood, as many marine organisms ingest microplastics. They are also present in the air we breathe, especially in urban areas with high levels of plastic waste. Research has shown that microplastics can have harmful effects on human health, including inflammation, oxidative stress, and potential disruptions to the endocrine system. Moreover, they are devastating to the ecosystem, harming wildlife and disrupting the balance of marine and terrestrial habitats.

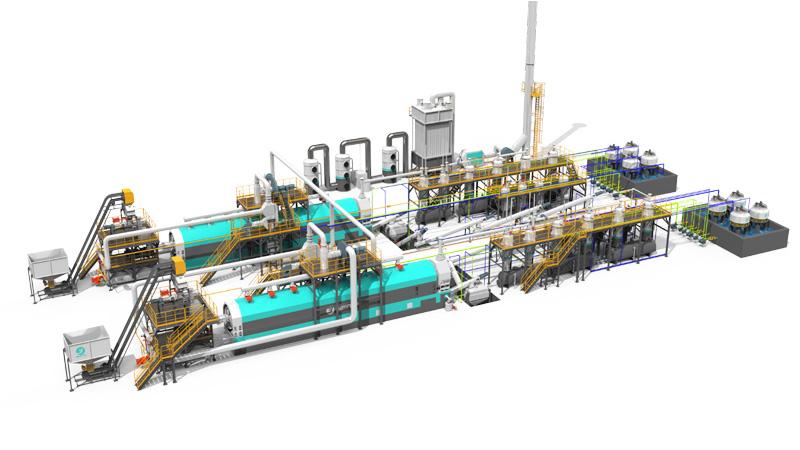

Pyrolysis is a thermal decomposition process that occurs in the absence of oxygen. When plastic waste is subjected to high temperatures (usually between 400 – 800°C) in a pyrolysis reactor of pyrolysis plant for sale, the long – chain polymer molecules of the plastic break down into smaller molecules. These smaller molecules can be in the form of gases, liquids, and solid residues.

The gas fraction can be used as a source of energy, similar to natural gas. The liquid fraction, often referred to as pyrolysis oil, can be further refined and used as a fuel or as a feedstock for the production of new plastics. The solid residue, mainly composed of carbon black, has applications in industries such as rubber manufacturing.

While pyrolysis shows great potential, there are still challenges to overcome. One of the main challenges is the cost – effectiveness of the process. Setting up a pyrolysis plant requires significant capital investment, and the operational costs, including energy consumption, can be high. However, as technology advances and economies of scale are achieved, the costs are expected to come down.

Another challenge is the quality control of the products obtained from pyrolysis. The composition of pyrolysis oil and gases can vary depending on the type of plastic waste used and the pyrolysis conditions. Standardization and further research are needed to ensure consistent product quality.

In conclusion, pyrolysis offers a glimmer of hope in the fight against plastic pollution. By efficiently converting plastic waste into valuable resources, it addresses multiple aspects of the plastic pollution problem, from reducing waste volume to curbing the microplastic menace. With continued research and development, and increased investment in this technology, pyrolysis could play a major role in creating a cleaner, more sustainable future. Let us all support the adoption and improvement of pyrolysis technology to combat the plastic pollution crisis.