Silicon EC Australia Offer Rebar Detailing Services to Better Serve Australian Construction Market

Construction in Australia has been growing at an impressive pace, with major infrastructure projects and commercial developments reshaping cities like Adelaide. With this growth comes the need for accurate, timely, and practical steel detailing. Even small errors in rebar drawings can create delays, cost overruns, or misalignments during fabrication and construction.

That’s where Silicon EC Australia steps in, offering comprehensive Rebar Detailing Services tailored specifically to the needs of the Australian construction market.

Adelaide’s construction scene is unique. Projects vary from high-rise residential buildings to complex industrial structures, each with its own set of challenges. Local contractors and engineers often need detailing services that can match project demands while remaining adaptable to evolving designs. By establishing a dedicated rebar detailing team in Adelaide, Silicon EC Australia is bridging the gap between design requirements and fabrication practicality.

Having experts on the ground ensures that structural drawings are not just theoretically correct but ready to translate seamlessly into the real world. This local presence reduces response time, supports faster project turnarounds, and strengthens collaboration with contractors and engineers across South Australia.

One of the main reasons construction projects experience delays is inaccurate or incomplete detailing. Misplaced bars, missing annotations, or incorrect dimensions can all create bottlenecks at the fabrication shop. With Silicon EC Australia’s Rebar Shop Drawings Services, these potential pitfalls are addressed proactively. Each drawing goes through a careful validation process to align with design specifications and practical fabrication constraints.

Shorter review cycles, combined with precise detailing, help construction teams avoid unnecessary revisions. Projects can move from design to fabrication more smoothly, keeping timelines tight and budgets under control.

For engineers and contractors, the process of translating design intent into practical rebar layouts can be challenging. Our team works closely with design offices to make sure every bar, stirrup, and mesh placement is documented clearly and logically. This collaboration minimizes miscommunication and ensures that Rebar Modeling aligns with the realities of fabrication and on-site assembly.

Whether it’s coordinating complex beam layouts or resolving tricky column reinforcement, Silicon EC Australia focuses on providing solutions that are easy to interpret, reducing the likelihood of errors during construction.

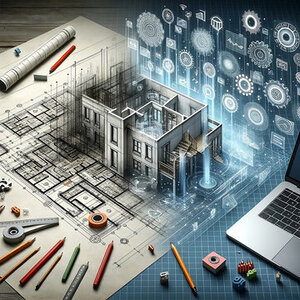

Silicon EC Australia combines traditional engineering expertise with modern digital tools. BIM-based workflows allow for accurate modeling of rebar, clash detection, and automated generation of shop drawings. This integration not only speeds up the detailing process but also helps teams visualize the structure before any fabrication begins.

Digital modeling ensures that the Rebar Detailing Services we provide are not only accurate but also flexible enough to accommodate design changes quickly. This reduces rework, keeps the fabrication shop busy with correct information, and ultimately saves time for contractors and engineers alike.

From small-scale commercial projects to large infrastructure developments, Silicon EC Australia tailors its detailing services to suit project complexity. The Adelaide team understands that each project has unique requirements. Our detailing packages are designed to adapt to these variations without compromising clarity or accuracy.

This flexibility is particularly important in fast-moving construction markets where designs evolve rapidly. By providing clear, validated Rebar Shop Drawings Services, teams can confidently move to fabrication without second-guessing the details.

While our services are grounded in the Australian market, Silicon EC Australia applies global best practices in rebar detailing. This ensures that projects are not just compliant with local codes but also meet international expectations for quality and constructability.

By combining local insight with global standards, engineers and contractors receive detailing that is practical, reliable, and ready to implement on-site. This approach reduces risk, avoids fabrication errors, and keeps projects on schedule.

Communication between designers, detailers, and contractors is often where challenges arise. Our Adelaide-based team emphasizes collaboration at every stage of the detailing process. Early involvement in design discussions allows us to anticipate issues before they appear in drawings.

Through proactive communication, detailed annotations, and clearly documented Rebar Modeling, our team ensures that everyone from engineers to fabrication shops has a common understanding of what is expected. This clarity translates into smoother project execution and fewer on-site surprises.

In construction, timing is everything. Late shop drawings can stall fabrication, delay concrete pours, and ripple through the entire project schedule. Silicon EC Australia focuses on providing reliable timelines without sacrificing quality.

Having a dedicated team in Adelaide means that projects receive attention quickly, and any changes in design can be integrated promptly. The combination of local presence and digital workflow capabilities allows us to deliver detailing that keeps construction moving efficiently.

Beyond accuracy and timelines, Silicon EC Australia’s approach emphasizes practical problem-solving during the detailing process. Every project brings unique challenges, whether it’s complex reinforcement layouts, tight construction schedules, or evolving design changes.

Our team works proactively to identify potential conflicts in advance, suggesting adjustments that make fabrication and on-site assembly smoother. By integrating digital modeling tools with hands-on expertise, we can visualize structures in 3D, which helps prevent clashes, reduces material waste, and optimizes reinforcement placement.

This level of foresight also allows contractors and engineers to plan their workflows more efficiently, ensuring that construction activities can progress without unnecessary interruptions.

Additionally, our Adelaide-based presence makes it easier to coordinate with local teams, conduct quick reviews, and provide timely clarifications. The combination of on-the-ground support and advanced modeling capabilities means projects receive detailing that is not only accurate but practical and ready to execute. Ultimately, our goal is to make the process of moving from design to fabrication seamless, providing construction teams with confidence in every drawing and reinforcing our commitment to supporting the Australian construction market effectively.

Silicon EC Australia’s rebar detailing services in Adelaide bring together technical expertise, local knowledge, and practical execution. From Rebar Detailing Services to Rebar Shop Drawings Services and Rebar Modeling, the focus is on producing accurate, clear, and fabrication-ready documentation that supports smooth project delivery.

For engineers, contractors, and builders in Adelaide and across South Australia, our presence means quicker response times, better coordination, and a reduction in errors that often slow construction.

Construction projects are complex, but the detailing doesn’t have to be. With the right team handling your rebar drawings, you can focus on building rather than fixing avoidable errors.