Structural steel detailing plays a critical role in modern construction, providing the precision and accuracy.

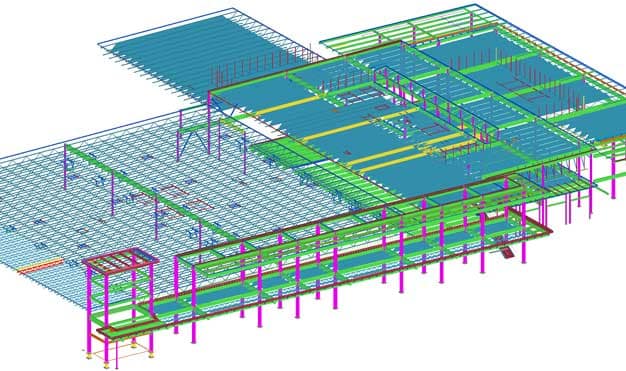

[Sydney-Australia, January-2025] One of the most significant developments in the field of Structural Steel Detailing is the widespread adoption of Building Information Modeling (BIM). BIM allows for the creation of detailed 3D models of the entire structure, including all steel components, enabling designers and engineers to visualize the entire project before any physical work begins. This comprehensive digital representation provides a higher level of accuracy and helps to identify potential issues early in the design process, reducing the likelihood of costly mistakes during construction.

BIM also facilitates better collaboration between various stakeholders, such as architects, engineers, contractors, and fabricators. By having access to a centralized model, all parties can work from the same source of information, minimizing misunderstandings and discrepancies between design and execution. Furthermore, the integration of BIM with other technologies, such as cloud-based platforms, allows for real-time updates, enabling faster decision-making and better coordination across the project lifecycle.

3D modeling is another technology that is transforming steel detailing. It offers a more detailed and accurate visualization of steel components compared to traditional 2D drawings, allowing for a clearer understanding of the design intent. 3D models can also be used to simulate the assembly process, helping fabricators to optimize their workflows and reduce errors. This visualization capability is particularly important for complex steel structures, such as bridges, high-rise buildings, and industrial plants, where precision is paramount.

Automation is increasingly making its way into the world of structural steel detailing, driven by advancements in computer-aided design (CAD) software and robotic manufacturing processes. Automated systems are now being used to generate detailed steel drawings and models based on input parameters, streamlining the design process and significantly reducing the time required for manual drafting. This allows steel detailers to focus on higher-value tasks, such as quality control and coordination, while the automation tools handle repetitive and time-consuming aspects of the work.

Robotics is also playing a role in the fabrication process, where machines are being used to cut, weld, and assemble steel components with high precision. These robotic systems, which can be integrated with steel detailing software, enhance efficiency and reduce human error, ensuring that each steel component is fabricated to exact specifications. This level of precision is especially important for large-scale projects, where the size and complexity of the steel structure can pose challenges during fabrication and assembly.

As automation and robotics continue to evolve, it is likely that we will see even greater integration of these technologies into the steel detailing process. In the future, it is possible that much of the detailing work, from initial design to fabrication, could be automated, reducing the need for manual input and further improving efficiency.

Artificial intelligence (AI) and machine learning (ML) are two emerging technologies that have the potential to revolutionize the structural steel detailing industry. AI can be used to analyze large amounts of data, such as historical project information, design specifications, and material properties, to identify patterns and optimize the detailing process. For example, AI algorithms could suggest design improvements or identify potential conflicts between steel components, allowing for faster and more accurate decision-making.

Machine learning, a subset of AI, has the ability to improve over time by learning from data and experience. In steel detailing, machine learning could be used to predict potential design issues based on previous project data or analyze construction site conditions to recommend the most efficient fabrication methods. Over time, this could lead to more streamlined processes, reduced costs, and fewer errors in the final structure.

While AI and ML are still in the early stages of adoption in the construction industry, they hold tremendous promise for the future of steel detailing. As these technologies continue to evolve, it is likely that they will become integral parts of the detailing process, helping to automate and optimize various aspects of the work.

Sustainability is a growing concern in the construction industry, and structural steel detailing is no exception. As the demand for more environmentally friendly buildings and infrastructure increases, the steel detailing industry is also exploring ways to reduce waste, optimize material usage, and lower the carbon footprint of steel production.

One way that steel detailing can contribute to sustainability is through the use of advanced software that helps to optimize the use of materials. By creating more accurate models and minimizing material waste during fabrication, steel detailers can reduce the overall environmental impact of a project. Additionally, the use of recycled steel and other sustainable materials in steel construction is becoming more common, and steel detailers will play a crucial role in ensuring that these materials are incorporated efficiently into the design.

The future of structural steel detailing is bright, with advancements in BIM, 3D modeling, automation, AI, and sustainability paving the way for greater efficiency, accuracy, and innovation in the industry. As these technologies continue to evolve, they will redefine how steel structures are designed, detailed, and fabricated, resulting in faster project completion times, reduced costs, and improved quality.

As the construction industry embraces these changes, steel detailers will need to stay ahead of the curve by adopting new technologies and developing the skills necessary to leverage them effectively. By doing so, they will continue to play a pivotal role in the success of modern construction projects, helping to shape the built environment for generations to come.

In conclusion, structural steel detailing is on the cusp of a technological revolution, and those who are able to embrace these emerging trends and technologies will be well-positioned to thrive in the future of construction

[Silicon Engineering Consultants Pty Ltd]