Pneumatic Control Valves: Functionality, Common Faults, and Troubleshooting

Pneumatic China control valves are essential in industrial automation, precisely regulating fluid and gas flow by converting compressed air pressure into mechanical motion. Their reliability and accuracy make them vital in processes requiring efficient flow management.

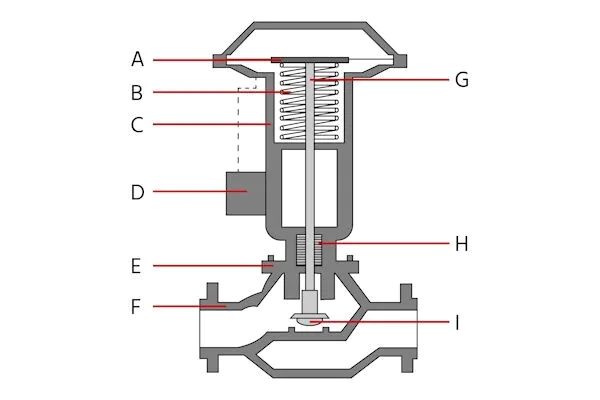

Actuator: Converts air pressure into mechanical movement to control valve position. There are two main types:

Diaphragm actuators use a flexible diaphragm, ideal for low-pressure and quick response applications.

Piston actuators use a piston, suitable for high-pressure environments.

Actuators may be single-acting (air moves valve one way; a spring returns it) or double-acting (air controls movement both ways).

Spring: In single-acting actuators, the spring acts as a fail-safe, returning the valve to a safe position if air pressure is lost.

Yoke: Connects and aligns the actuator with the valve body, ensuring stability and reducing vibration.

Positioner: Receives control signals and adjusts the actuator for precise valve positioning. Types include pneumatic, electro-pneumatic, and digital positioners, with increasing accuracy and communication features.

Bonnet: Covers the valve stem and internal parts, providing a pressure-tight seal and access for maintenance.

Valve Body: Houses critical flow control parts like the seat and plug. Common valve body types are globe (precise throttling), ball (quick open/close), butterfly (large flow), and gate (on/off control).

Valve Stem: Links the actuator to the plug or disc, transmitting movement while withstanding stresses.

Seals and Gaskets: Prevent leaks within the valve assembly, essential for efficiency and safety.

Valve Seat and Plug: Regulate flow by opening or closing the valve. Material quality and precision are crucial for sealing and durability.

Air Leaks: Worn seals, loose fittings, or damaged hoses can cause air leaks, weakening actuator response and valve operation.

Sticking or Jamming: Debris, corrosion, or rust can block valve movement, leading to control loss.

Actuator Failure: Wear or air pressure loss can cause actuator malfunction, leaving the valve stuck.

Positioner Malfunction: Miscalibration or electrical issues can cause incorrect valve positioning and flow errors.

Seal Wear: Damaged seals cause leakage, reducing efficiency and potentially risking safety.

Review Maintenance History: Check for recurring issues to understand if the problem is ongoing or new.

Visual Inspection: Look for wear, corrosion, leaks, or damage on the valve, actuator, yoke, and bonnet.

Air Supply Check: Verify proper air pressure with a gauge; inspect hoses and fittings for leaks or blockages.

Actuator Testing: Manually operate the actuator, listen for leaks, and confirm it receives correct pressure and signals.

Positioner Calibration: Recalibrate the positioner per guidelines; inspect wiring and signal quality.

Control Signal Verification: Ensure signals are accurate and free from interference.

Manual Valve Operation: Check for smooth movement and unusual noises indicating internal wear.

Internal Inspection: Disassemble if needed to clean and replace worn seats, plugs, stems, seals, or gaskets.

Pipeline Check: Inspect connected pipelines for blockages or corrosion that may affect valve performance.

Pneumatic control valves are vital for precise automated flow control in industrial systems. Understanding their components, common issues, and how to troubleshoot effectively helps maintain operational reliability, improve safety, and reduce downtime. Regular maintenance and prompt repairs ensure these valves perform optimally in demanding environments.Know more about Google SEO Directory