Strategic guide for selecting a high-quality limestone crusher. Emphasizes durability, typologies, and minimizing total cost.

The acquisition of a limestone crusher is a capital investment that reverberates through the entire operational and financial fabric of a quarry or mining operation for years, if not decades. This is not a purchase to be approached with catalog-skimming nonchalance or a singular focus on the sticker price. It is a strategic decision, a complex equation where the variables of geology, mechanical engineering, and long-term economics intersect. A quality machine, perfectly matched to its duty, becomes a silent, relentless engine of profit. A misapplied or poorly constructed one becomes a voracious sinkhole of downtime, repair costs, and missed opportunity. The path to a successful acquisition is paved not with haste, but with meticulous forensic analysis and an unwavering emphasis on intrinsic, engineered quality over superficial appeal.

Every successful crusher acquisition begins not with a machine specification, but with a deep and unsparing interrogation of the very material it must process. The characteristics of your limestone are the uncompromising dictator of suitable technology. Its compressive strength, abrasiveness, silica content, and natural fissility are not mere data points; they are the foundational constraints that will determine the success or failure of your investment. A limestone crusher perfect for soft, friable limestone will be swiftly annihilated by a hard, abrasive, and high-silica variety. Simultaneously, you must define your operational ambition with ruthless clarity. “High capacity” is a meaningless phrase without context. True capacity is a function of desired product size, the machine’s closed-side setting, and the specific density and feed size of your material. Understanding the interplay between these factors—the raw, unyielding nature of your rock and the precise commercial goals you must meet—is the indispensable first principle of acquisition.

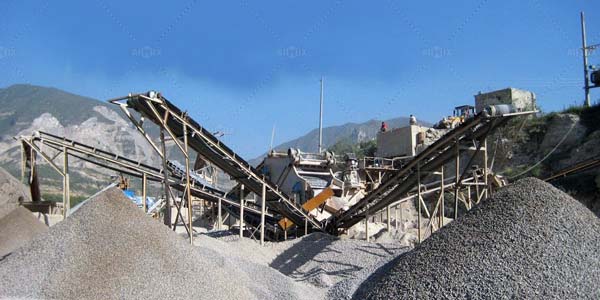

The market presents a lexicon of crushing technologies, each with a distinct philosophy of applying force to rock. Misunderstanding these typologies is a primary source of catastrophic misapplication. Jaw crushers are the titans of primary reduction, masters of immense compressive force. They excel at breaking massive quarry-run shot rock into manageable, coarse aggregate. Their limitation is inherent in their mechanism; they offer less control over product shape and generate a higher proportion of elongated particles. For secondary and tertiary reduction, the choice bifurcates. Cone crushers are the precision instruments of compression crushing. They utilize a gyrating mantle within a concave bowl to progressively crush rock to a predetermined cubical shape, making them ideal for high-quality aggregate production. Impact crushers, by contrast, are the masters of kinetic energy. They hurl rock against hardened aprons or anvils or instigate rock-on-rock collisions, achieving excellent reduction ratios and often a more favorable particle shape for certain applications, albeit potentially at a higher wear cost in abrasive environments. Selecting between them is a strategic choice dictated by your product specification and the abrasiveness of your feed.

The true quality of a crusher is not found in its painted exterior but in the unseen architecture of its core components. This is where engineering pedigree separates itself from mere assembly. The metallurgical alchemy of its wear parts—mantles, concaves, jaw dies, blow bars—is paramount. Are they crafted from proprietary alloys, meticulously heat-treated to achieve the perfect balance of surface hardness for abrasion resistance and core toughness to withstand impact shatter? The bearing systems are the heart of the machine; oversized, precision-rated bearings operating well within their load and thermal limits are a hallmark of quality, ensuring smooth operation and preventing the catastrophic failures that spell weeks of downtime. Furthermore, the rotational mass and structural integrity of the main frame and rotors speak to a machine built to absorb years of punishing vibration and shock loads without fatigue. These are the components that silently dictate your maintenance schedule, your parts inventory, and ultimately, your total cost of ownership.

The final selection must be the result of a clear-eyed total ownership calculus, a framework that looks far beyond the initial capital outlay. This calculus synthesizes the purchase price with the projected costs of energy consumption, wear parts replacement, routine maintenance labor, and, most critically, the potential revenue lost to unscheduled downtime. A marginally cheaper machine constructed from inferior materials and with non-standardized components will reveal its true cost within the first year of operation, its constant demands for attention and repair eroding any initial savings many times over. The verdict, therefore, must align machine pedigree with operational reality. It requires partnering with a manufacturer whose engineering philosophy prioritizes longevity and reliability, and whose support network can provide timely technical expertise and parts availability. The successful acquisition is not merely the purchase of a machine; it is the strategic enlistment of a reliable, high-performing partner in your pursuit of operational excellence and profitability.

Acquiring a world-class machine is merely the prelude to a long-term performance symphony. Its operational lifespan and sustained output quality are irrevocably tied to the culture of maintenance instilled from its first day of operation. This transcends reactive repairs; it is the doctrine of proactive stewardship. Implementing a rigorously scheduled regimen, informed by the manufacturer’s guidance but tailored to your specific operational intensity, is non-negotiable. This includes systematic lubrication using specified grades of oil, meticulous monitoring of wear part tolerances, and periodic laser alignment of drives and motors. Vibration analysis and thermal imaging can detect nascent failures long before they become audible or catastrophic. This vigilant, data-driven approach transforms the crusher from a passive asset into a responsive component of your operation, whose maintenance needs are predicted and planned for, not reacted to. This final step ensures the sophisticated engineering embedded within your machine is fully realized and protected throughout its entire service life.

A limestone crusher, no matter how technologically advanced, does not operate in a vacuum. Its efficiency, productivity, and even its longevity are profoundly influenced by the human element. The operator is not merely a controller but an interpreter of the machine’s language—its sounds, its vibrations, its performance metrics. Investing in comprehensive, hands-on operator training is therefore not an ancillary cost but a critical capital protection strategy. A skilled operator can discern the subtle change in crusher rumble that indicates a cavity-level issue, adjust feed rates to prevent choking or running empty, and identify the optimal operational rhythm that maximizes yield while minimizing wear. This deep, intuitive symbiosis between human expertise and mechanical force elevates the equipment from a simple tool to a true force multiplier, ensuring that the sophisticated capabilities designed into the machine are fully and effectively utilized.