Optimize textile operations with Odoo API integration automate production, sync inventory.

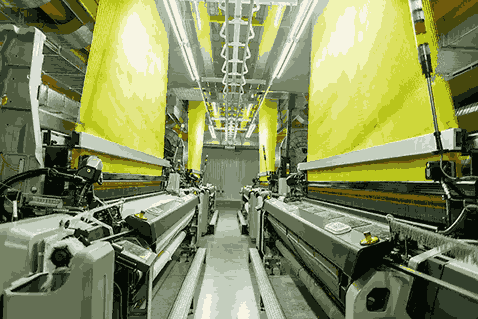

Businesses in the fast-paced textile sector of today oversee a variety of systems, from vendor interactions and client orders to inventory tracking and machine operations. However, inefficiencies increase when these systems function in isolation. Poor demand forecasting, miscommunication with suppliers, and production delays can result from manual data entry, delayed updates, and inconsistent reporting. Unifying different apps and ensuring synchronised, real-time data flow throughout the entire operation are made possible by Odoo API connectivity.

Textile producers may easily integrate other platforms, such as CAD software, IoT-enabled machinery, warehouse automation tools, and shipping services, into a single ERP ecosystem by utilising a competent odoo api integration services. Actionable insights from centralised data are made possible by this link, which also removes redundant operations and lowers mistake rates. Businesses benefit from increased operational control, quicker production cycles, and improved decision-making skills that enable scalable expansion as a result.

Real-Time Data Sync: Instant updates across systems ensure accurate inventory levels, production status, and delivery timelines.

Reduced Manual Errors: Automation of data exchange lowers human errors in order processing, inventory counts, and vendor coordination.

Accelerated Production Cycles: Streamlined data flow helps optimize machine usage, reduce downtime, and meet deadlines efficiently.

Enhanced Supplier Collaboration: APIs integrate supplier portals directly, improving transparency and procurement timing.

Cost Reduction: Reduced redundancies and improved process efficiency help cut down operational and administrative costs.

Scalable Infrastructure: APIs support easy system expansion as the business grows without major re-engineering or system downtime.

CAD to ERP Design Sync: Automatically import garment designs from CAD software into Odoo to initiate production planning instantly.

IoT Machine Monitoring: APIs connect IoT devices with Odoo, enabling real-time machine performance monitoring and predictive maintenance alerts.

Automated Order Processing: Orders placed online are instantly synced with inventory, invoicing, and production queues without manual intervention.

Barcode & RFID Scanning: Warehouse data is updated live using scanning devices connected via APIs to manage raw materials and finished goods.

Production Scheduling Automation: APIs enable dynamic allocation of tasks to production lines based on workload, reducing bottlenecks.

Quality Control Integration: QC systems share inspection data directly into Odoo, ensuring non-compliant batches are flagged and reworked efficiently.

Shipping & Logistics Providers (e.g., DHL, FedEx): APIs enable real-time shipment tracking and automated label generation directly from Odoo.

Raw Material Vendor Portals: Vendors can push inventory updates, invoices, and dispatch notices to Odoo for faster procurement cycles.

E-commerce Platforms (e.g., Shopify, Amazon): Order, stock, and pricing data sync automatically between online stores and the Odoo backend.

Third-Party Warehousing (3PLs): Live inventory and order fulfillment updates from 3PL providers are integrated for streamlined warehouse management.

Freight & Customs Systems: Integration allows for auto-calculation of duties, customs documentation, and regulatory compliance.

Payment Gateways (e.g., Razorpay, Stripe): APIs enable seamless transaction processing and payment reconciliation within the ERP system.

B2B CRM and Order Portals: Distributors and wholesalers can place orders and view availability through integrated CRM portals synced to Odoo.

Maintaining platform coherence becomes crucial when textile firms implement new manufacturing, logistics, and customer management systems. Your ERP will be able to easily interface with supplier platforms, customer touchpoints, and emerging technologies thanks to odoo api integration. It maximises your present investments while future-proofing operations.For textile companies, Odoo API connection is a scalable investment since it unifies several systems including manufacturing, inventory, sales, and logistics under a single, intelligent ERP ecosystem. Synchronised data flow between departments and partners becomes essential as textile processes expand in scale and complexity.

Business Process Audit: Analyze current operations to identify where data silos and inefficiencies exist.

Define Integration Goals: Set clear objectives for what systems need to connect and what data needs to flow between them.

API Mapping & Design: Plan the API architecture, including data endpoints, triggers, and response formats tailored for textile use cases.

Implementation & Testing: Integrate systems gradually, starting with core processes, and test for performance, accuracy, and resilience.

Staff Training & Change Management: Educate users on new workflows and dashboards to ensure smooth adoption and consistent data handling.

Continuous Monitoring & Optimization: Use analytics to track integration performance and refine configurations as business needs evolve.