Avoid common crusher plant mistakes with expert tips on material handling, maintenance, and safety for optimal performance.

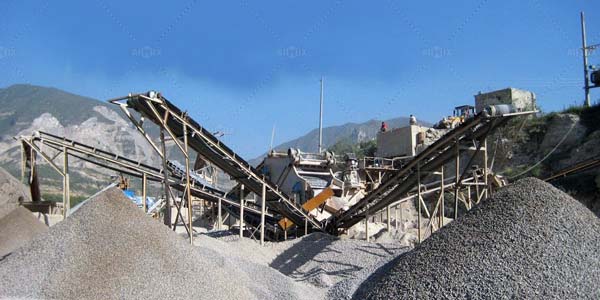

Crusher plants are indispensable in mining, quarrying, and construction industries. They transform large rocks into smaller aggregates, ensuring an efficient supply of materials for various projects. However, improper use of these powerful machines can lead to inefficiencies, breakdowns, and costly delays. Many operators, especially those new to the industry, inadvertently commit avoidable mistakes that hinder productivity and damage equipment.

By understanding the most common errors, businesses can optimize crusher plant performance, prolong machinery lifespan, and enhance operational safety. This article delves into frequent missteps and provides expert advice on mitigating them effectively.

One of the most overlooked yet critical aspects of crusher efficiency is material size consistency. Introducing oversized or mixed-dimension materials causes uneven wear on crusher components. Excessively large rocks exert extreme pressure on the crushing mechanism, potentially leading to mechanical failures.

To mitigate this, operators should use a pre-screening system or a grizzly feeder to eliminate oversized materials before they reach the primary crusher. Consistently feeding appropriately sized materials ensures uniform crushing performance and extends equipment longevity.

Exceeding the crusher’s capacity is a common yet avoidable error. Overloading leads to excessive wear, increased power consumption, and potential motor burnout. Many operators mistakenly assume that running aggregate crusher at full capacity maximizes output, but in reality, it often reduces overall efficiency due to increased downtime caused by blockages and overheating.

Using an automated load monitoring system helps maintain optimal feed levels. Operators should adhere to the manufacturer’s recommended capacity and implement real-time monitoring systems to prevent overloading.

Crusher plants contain numerous moving parts that require consistent lubrication to function effectively. Insufficient lubrication results in increased friction, overheating, and premature wear of bearings and other crucial components.

Operators should establish a scheduled lubrication routine, ensuring all critical parts receive the necessary grease or oil. Using high-quality lubricants designed for heavy-duty machinery enhances performance and minimizes wear.

Routine inspections are vital in identifying wear before it escalates into catastrophic failure. Conveyor belts, liners, and jaw plates endure constant abrasive forces, making them prone to deterioration.

Operators should perform frequent inspections and replace worn components promptly. Proactive maintenance reduces unplanned downtime and extends the plant’s operational life.

Untrained personnel operating a crusher plant pose significant risks to themselves and the equipment. Lack of knowledge about correct operational procedures often leads to improper machine handling, increased accident rates, and suboptimal performance.

Comprehensive training programs should be implemented to ensure all personnel understand safety protocols, emergency shutdown procedures, and efficient operating techniques.

Crusher plants generate substantial dust and noise pollution, affecting both worker health and the surrounding environment. Failure to implement effective control measures can lead to respiratory issues and regulatory non-compliance.

Installing dust suppression systems, using noise-reducing enclosures, and mandating protective gear for workers help mitigate these hazards.

Preventing common mistakes in crusher plant operations requires a combination of proper material handling, regular maintenance, and stringent safety measures. By proactively addressing these issues, businesses can ensure their crushing plants operate at peak efficiency, reducing downtime and increasing profitability. Investing in training, monitoring equipment loads, and enforcing strict maintenance schedules are essential steps toward achieving long-term operational success.

© 2024 Crivva - Business Promotion. All rights reserved.