This blog primarily examines the crucial issues and pertinent features to consider when selecting a VUV camera for vacuum applications.

Such as those that have neither air nor conditions close to atmospheric pressure, in space, inside particle accelerators, and ultra-high vacuum (UHV) laboratories, imaging can be quite a unique challenge. Vacuum cameras, mainly of the type optimised for Vacuum Ultraviolet (VUV) detection, are very vital in obtaining accurate images and measures under such conditions. They are highly specialised systems that must operate in a challenging environment while maintaining precise performance, reliability, and resolution. This document primarily examines the crucial issues and pertinent features to consider when selecting a VUV camera for vacuum applications.

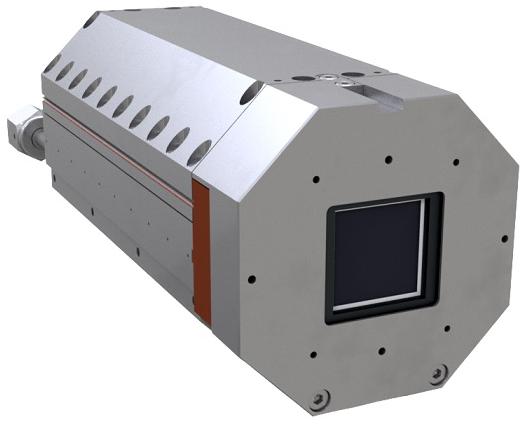

A VUV camera is an imaging tool, particularly designed to detect vacuum ultraviolet (VUV) light, which spans wavelengths from approximately 10 nm to 200 nm. Since VUV photons are strongly absorbed by air, these cameras are always utilised in vacuum chambers, hence the dual need for vacuum compatibility and VUV sensitivity. They are critical in applications like synchrotron radiation imaging, plasma diagnostics, semiconductor lithography, and floor technology.

This is the most important condition: operation in high-vacuum (HV) or ultra-high-vacuum (UHV) conditions. Cameras used in such environments must be made of materials that:

Protective windows cover the standard camera sensor. However, VUV light gets absorbed in most materials, so designers of VUV CCD cameras can use:

Most VUV-sensitive cameras use back-thinned, back-illuminated CCD or CMOS sensors to maximise quantum efficiency (QE) in the VUV spectrum. These sensors eliminate the front circuitry layer, allowing photons to strike the photosensitive area directly with minimal loss.

Vacuum cameras employ thermoelectric (Peltier) cooling or liquid nitrogen cooling to minimise dark current and improve signal-to-noise ratios during long exposures. Proper thermal management becomes even more important, considering convection cooling is not possible in vacuum environments.

In environments like synchrotrons or fusion reactors, radiation poisoning makes the camera components degrade. Cameras used in those areas shall have:

Purchasing a VUV CCD camera is not merely about checking resolutions or prices; it means understanding the environmental conditions, the desired spectral sensitivity, and the integration requirements. Whether imaging a plasma jet, analysing a high-energy beamline, or studying quantum materials being used under vacuum, one solution is a well-designed VUV CCD camera.

Manufacturers will offer both ready-made off-the-shelf options and custom solutions for VUV imaging applications. Always consult the experts regarding technical issues to ensure compatibility with both your vacuum system and scientific goals.