Understanding the Single-Seated Globe Control Valve: Design, Operation, and Industrial Applications

Introduction

We are a leading control valve manufacturer in China, providing high-performance valves and control actuators designed to meet a wide range of industrial requirements.

In fluid control systems, the single-seated globe control valve remains one of the most widely used and reliable components across industries. Known for its compact design, precise modulation, and effective sealing, this valve plays a vital role in ensuring process stability and efficiency. A standout feature is its interchangeable trim, allowing adaptability to varying process conditions simply by replacing internal components—making it suitable for controlling steam, liquids, and gases.

Key Applications

This valve is ideal for scenarios requiring tight shutoff, fine control, and operational flexibility. Common applications include:

Steam control systems

Chemical processing

Oil and gas operations

Power generation

Pharmaceutical production

Water treatment facilities

By adjusting plug shapes and seat ring sizes, engineers can optimize flow characteristics, pressure, and temperature control to meet diverse process needs.

Structural Overview

The single-seated globe valve features a straightforward linear-motion mechanism that moves a plug against a seat to regulate flow. This design offers excellent sealing performance and is especially effective in low- to medium-pressure systems. However, since unbalanced pressure acts directly on the plug, allowable pressure drops are limited—making this valve less suitable for high-pressure applications without additional design considerations.

Control Mechanism: Pneumatic Actuation

Typically paired with pneumatic actuators, these valves respond rapidly and safely to control signals. Pneumatic systems are widely favored for their:

Fast response

Fail-safe functionality

High safety in explosive environments

Compatibility with automated control systems

Control signals from DCS or PLC systems are transmitted to smart positioners, which adjust the valve stem accordingly. Accessories like solenoid valves, air filters, and volume boosters further enhance system responsiveness and stability.

Advantages of Single-Seated Globe Valves

Tight Shutoff – Ensures minimal leakage due to direct plug-to-seat contact.

High Controllability – Trim customization enables equal percentage, linear, or quick-opening flow profiles.

Ease of Maintenance – Fewer internal components reduce downtime and servicing costs.

Compact Design – Suitable for installations with space constraints.

Modular Trim – Internal trims can be replaced without changing the entire valve.

Design Considerations

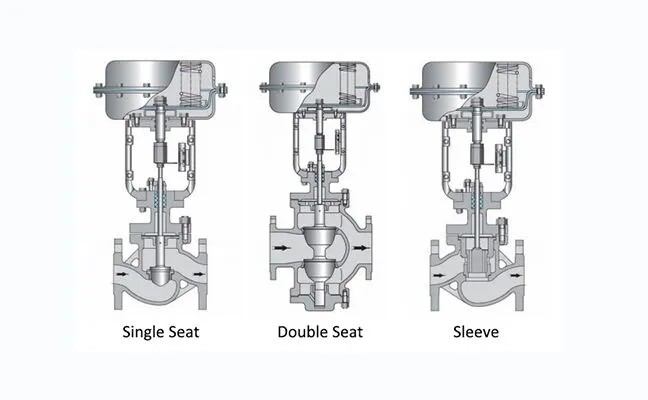

The primary limitation is the unbalanced force on the plug at higher pressure differentials, which may require larger actuators or alternate valve designs (e.g., double-seated or pressure-balanced trims) in such applications.

Media Versatility

These valves are compatible with a wide range of media:

Liquids – Clean applications requiring tight shutoff

Gases – With proper sealing materials

Steam – High thermal tolerance makes them ideal for steam control

Corrosive fluids – Available in corrosion-resistant materials like stainless steel and Hastelloy

Automation Integration

Modern single-seated globe valves support smart integration with HART, Foundation Fieldbus, and Profibus systems, enabling remote diagnostics, monitoring, and real-time adjustments.

Real-World Application

In a chemical plant managing heat-sensitive liquids, a stainless steel single-seated globe valve with an equal percentage plug profile and pneumatic actuator ensured stable temperature and flow control. The integration of a digital positioner helped the plant reduce energy use and minimize product waste.

Conclusion

The single-seated globe control valve offers a reliable, efficient, and adaptable solution for precise flow regulation. While it may have limitations under high pressure, its benefits in controllability, maintainability, and automation readiness make it a preferred choice in diverse industrial applications.Know more about Google SEO Directory