Single-Seated Globe Control Valves: Precision and Reliability in Flow Control

In fluid control systems, the single-seated globe control valve is a proven solution valued for its precision, compact design, and tight shutoff capabilities. Its ability to provide stable flow regulation makes it a critical component across industries such as oil and gas, chemical processing, power generation, and pharmaceutical manufacturing.

A key feature is its interchangeable trim, allowing engineers to modify internal components—such as plugs and seat rings—to meet specific flow and pressure conditions. This adaptability makes the China Control Valve ideal for managing various media, including liquids, gases, steam, and corrosive fluids.

Single-seated globe valves are used wherever accurate control and minimal leakage are essential. Common applications include:

Steam distribution systems

Chemical dosing and mixing

Process temperature and pressure control

Water treatment and utility regulation

With customizable trim designs, they can be tuned for linear, equal percentage, or quick-opening flow characteristics, providing flexibility in controlling system variables.

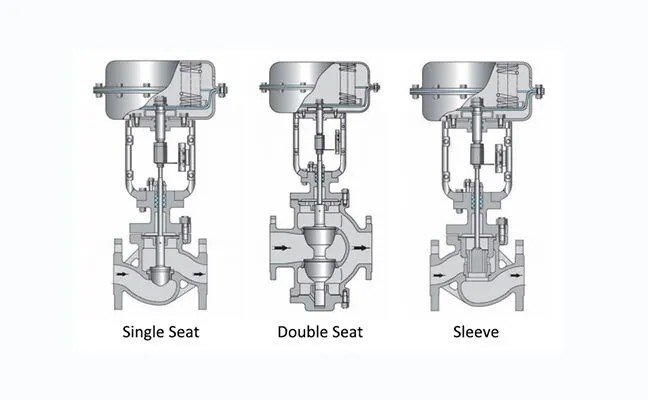

The valve’s core design features a single plug that moves vertically into a seat ring to modulate flow. This linear motion offers precise control and excellent shutoff performance.

Compared to balanced trim valves, single-seated valves experience higher unbalanced forces due to the full pressure drop acting across the plug. As a result, they are best suited for low to moderate pressure drops unless paired with larger actuators.

Most single-seated globe valves are actuated pneumatically, using compressed air to drive the valve stem via a diaphragm or piston actuator. Pneumatic systems are preferred for their:

Fast response times

Fail-safe operation

Safety in explosive environments

Compatibility with automation systems

Control signals from a digital positioner or Distributed Control System (DCS) direct the actuator to adjust valve position in real time. Accessories such as solenoid valves, air filters, and position feedback systems enhance functionality and reliability.

Single-seated globe control valves offer multiple benefits:

Tight Shutoff – The single plug-seat design ensures minimal leakage.

High Precision – Interchangeable trims allow for accurate flow modulation.

Compact Footprint – Ideal for space-constrained environments.

Ease of Maintenance – Fewer internal components reduce downtime.

Media Versatility – Compatible with clean liquids, steam, gases, and corrosive fluids when built with appropriate materials.

Due to higher unbalanced forces, these valves are less suitable for high differential pressure applications unless used with reinforced actuators. For such scenarios, balanced trim or double-seated valves may be preferred to reduce actuator load.

The single-seated globe control valve remains a dependable solution for precise flow control and tight shutoff in various industrial processes. Its simple construction, pneumatic actuation compatibility, and trim flexibility make it a smart choice for modern process systems seeking both performance and reliability. Whether managing steam, chemicals, or water, this valve continues to meet the demands of evolving automation and control environments.Know more about Google SEO Directory