Pneumatic Wafer Butterfly Valves: Structure, Features, Applications, and Maintenance

Pneumatic wafer butterfly valves have become essential components in many industries due to their efficient flow control, compact design, and ease of use. As one of the most widely used types of control valves, they are prized for their lightweight construction, rapid operation, and high reliability. Their structural versatility and straightforward installation make them ideal for a broad range of applications—from chemical processing plants to water treatment facilities.

This article explores the structure, key features, industry applications, installation procedures, maintenance tips, and operational guidance for pneumatic wafer butterfly valves. By the end, you’ll have a comprehensive understanding of why these valves are an indispensable choice in modern fluid control systems.

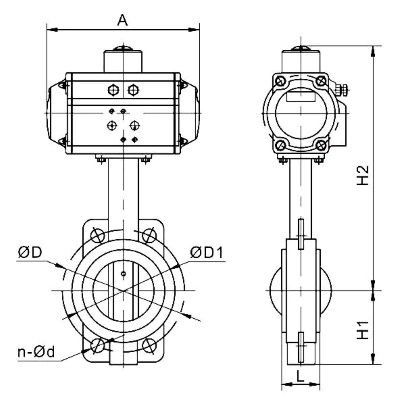

Pneumatic wafer butterfly valves consist of two main components:

A pneumatic actuator, powered by compressed air

A butterfly valve body, containing a rotating disc for flow control

The “wafer” designation refers to the installation method—sandwiched between two pipeline flanges, secured with bolts that pass through both flanges and the valve body.

When compressed air enters the actuator, it rotates the valve stem and disc. The disc’s angle determines whether fluid flow is allowed, throttled, or blocked. This mechanism enables fast response, precise control, and seamless integration into automated systems.

Compact & Lightweight

Easy to transport, install, and maintain

Reduces stress on pipelines and support structures

Easy Installation & Maintenance

Installed between flanges with fewer bolts than lug-type valves

Simplified disassembly and part replacement

Simple, Efficient Structure

Fewer components reduce failure risks and improve reliability

Low Operating Torque

Disc design reduces flow resistance and actuator size

Quick 90° Rotation

Fast opening and closing for high-cycle operations

Excellent Flow Characteristics

Minimal pressure drop and good throttling performance

Pinless Disc-to-Stem Connection

Prevents leakage and enhances structural durability

Spherical Disc Profile

Ensures uniform sealing and extends seat life

Replaceable Sealing Components

Allows for cost-effective maintenance and long service life

Disc Coating Options

PTFE, nylon, and other coatings for chemical resistance or food-grade applications

Flexible Connections & Actuation

Available in flange versions; supports manual, electric, or pneumatic operation

Chemical Processing

Handles corrosive and hazardous media reliably

HVAC Systems

Regulates airflow and chilled water efficiently

Water Treatment

Manages clean water distribution and wastewater systems

Food & Beverage

Sanitary designs with PTFE coatings for contamination-free processing

Pharmaceutical

High-precision control in clean environments

Pulp & Paper

Withstands abrasive slurries and chemicals

Pipeline Preparation

Ensure flanges are aligned to prevent stress and leakage.

Pre-Installation Inspection

Check components for cleanliness and integrity before installation.

Valve Positioning

Install in the closed position for proper seating.

Actuator Alignment

Ensure correct orientation and alignment with valve body before tightening.

Bolt Tightening

Apply even torque across all bolts for a secure seal.

Air Pressure

Supply air at standard pressures (typically 0.4–0.6 MPa).

Manual Testing

Manually operate the solenoid for initial movement checks.

Stroke Adjustment

Fine-tune actuator stroke if the valve sticks at the beginning of travel.

Smooth Operation

Ensure unobstructed disc movement and proper sealing.

Speed Control

Use adjustable flow restrictors to control actuator speed. Avoid over-restricting.

Routine Inspections

Check seals, actuators, and solenoid valves regularly.

Lubrication

Periodically lubricate moving parts in harsh environments.

Seal Replacement

Replace worn seals to maintain leak-free performance.

Actuator Care

Inspect for air leaks or sluggish behavior; clean air lines and solenoids as needed.

Service Records

Maintain documentation for tracking performance and anticipating issues.

Pneumatic wafer butterfly valves are indispensable for efficient and precise fluid control in diverse industries. Their innovative design, reliable performance, and adaptability to various media and environments make them a go-to solution in modern systems.

From rapid actuation to durable sealing, these valves are engineered for performance and long-term reliability. When installed and maintained properly, they contribute to operational safety, efficiency, and reduced maintenance costs.

Choosing a high-quality valve and following best practices in installation and upkeep ensures maximum system performance and a solid return on investment.Know more about Google SEO Directory