Pneumatic Wafer Butterfly Valves: Efficient, Reliable Flow Control

We are a leading China control valve manufacturer, delivering high-quality valves and control actuators customized to meet a wide range of industrial requirements.

Pneumatic wafer butterfly valves are widely used across industries for their quick operation, compact design, and reliable sealing. Their unique wafer-style installation—sandwiched between two pipeline flanges—makes them a cost-effective and space-saving solution for fluid regulation in systems such as chemical processing, water treatment, HVAC, and more.

This article explores the structure, key features, applications, installation guidance, and maintenance tips for pneumatic wafer butterfly valves—highlighting why they’re essential to modern fluid control systems.

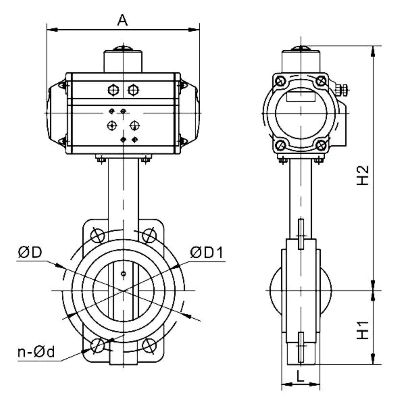

These valves consist of two main components: a pneumatic actuator and a butterfly valve body. The actuator uses compressed air to rotate the valve stem, turning the internal disc to open, throttle, or close the valve. The wafer design allows easy installation between flanges using through bolts, making it suitable for confined spaces and straightforward pipeline integration.

Compact & Lightweight

Minimalist construction simplifies transport, installation, and maintenance while reducing system load.

Simple Structure

Fewer parts (disc, stem, seat, body, actuator) mean lower failure rates and easy servicing.

Fast 90° Rotation

Rapid cycling ensures responsive flow control—ideal for automation.

Low Operating Torque

Streamlined disc design reduces resistance, requiring less energy to operate.

Excellent Sealing & Flow

Spherical disc edges improve sealing integrity, while linear flow minimizes pressure loss.

Pinless Stem-Disc Connection

Eliminates leak paths common in traditional pinned assemblies.

Replaceable Seat & Seals

Maintenance is simplified and valve life extended by replacing individual components.

Disc Coating Options

Coatings like nylon or PTFE enhance corrosion resistance and hygiene in specialized applications.

Flexible Operation Modes

In addition to pneumatic actuators, manual and electric options are available for diverse control needs.

Chemical Plants – Handles corrosive or hazardous fluids with durable materials and tight sealing.

Water Treatment – Regulates clean and wastewater flows efficiently.

HVAC Systems – Controls chilled/hot water and air distribution.

Food & Beverage – Sanitary operation with FDA-approved coatings.

Pharmaceuticals – Maintains hygiene and process accuracy.

Pulp & Paper – Withstands abrasive media like slurry and chemicals.

Align pipeline flanges to avoid stress.

Pre-inspect the valve and actuator for damage or debris.

Install the valve in a closed position for proper alignment.

Ensure actuator orientation matches system layout.

Tighten flange bolts evenly to prevent leaks.

Maintain air pressure between 0.4–0.6 MPa.

Manually test operation via the solenoid valve.

Adjust actuator stroke if the valve hesitates at opening/closing.

Fine-tune opening/closing speed using restrictors—avoid over-restricting.

Inspect seals and actuators regularly.

Lubricate moving parts to ensure smooth performance.

Replace worn sealing components as needed.

Clean air supply and solenoid connections routinely.

Keep service records to track performance and plan proactive maintenance.

Pneumatic wafer butterfly valves deliver cost-effective, responsive, and low-maintenance flow control. Their modular design, quick actuation, and broad material compatibility make them indispensable across fluid handling systems. By choosing quality valves and adhering to proper installation and maintenance practices, users can ensure long-term reliability and performance in even the most demanding environments.Know more about Google SEO Directory