Performance Features of Pneumatic Diaphragm Single-Seat Control Valve

The pneumatic diaphragm single-seat control valve is a key component in industrial automation systems, designed to regulate fluid flow with high precision and efficiency. Powered by compressed air, the valve uses a diaphragm to transmit force to the stem, which then adjusts the movement of a globe valve. This ensures seamless control of fluid mediums in pipelines, making it essential for industries requiring reliable and accurate flow management.

These valves often include essential accessories like valve positioners, solenoid valves, and converters, enhancing functionality for on/off control or proportional regulation based on automation control system signals.

Compact and Lightweight Design

The small size and reduced weight simplify installation and reduce space requirements in compact system configurations.

High Performance and Capacity

These valves handle high-capacity operations efficiently, ensuring optimal system performance.

IEC Standards Compliance

Designed to meet IEC standards, they offer compatibility and reliability across various industrial applications.

Versatile Applications

Suitable for different fluid mediums and process conditions, these valves are adaptable to a wide range of industries.

Innovative Actuator Design

Featuring a multi-spring diaphragm actuator, these valves are lightweight, easy to install, and easy to calibrate, ensuring smooth and precise operation.

Enhanced Flow Design

The valve body features a low-flow resistance channel, increasing the rated flow coefficient by 30%, which promotes smoother fluid movement and improves system efficiency.

Pneumatic diaphragm single-seat control valves play a critical role in industrial automation, directly influencing the efficiency, quality, and safety of production processes. Their widespread adoption is due to their:

Simple Design: Easy to use and maintain, minimizing downtime.

Intrinsic Safety: Operates safely under diverse conditions, minimizing operational risks.

Wide Application Range: Effective in both simple and complex fluid control processes.

The top-guided design offers several benefits:

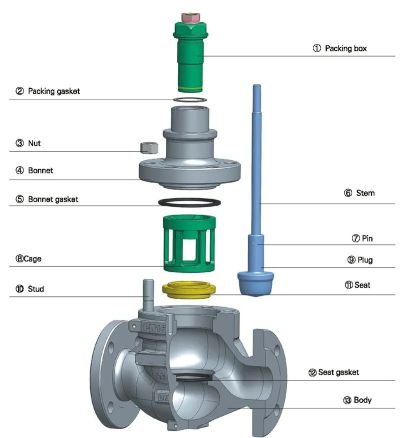

Compact Structure: With fewer components, these valves are easier to maintain, ensuring long-term reliability.

Leakage Options: Available in Metal-to-Metal (Class IV) and Soft Seal (Class VI) versions, catering to high-pressure or airtight sealing applications.

Large Adjustable Range: The 50 adjustable ratio allows flexibility in managing flow rates.

Pneumatic diaphragm single-seat control valves are highly versatile and used in various industries:

Oil and Gas: Regulate flow in pipelines, especially in high-pressure environments.

Chemical Processing: Manage corrosive and volatile fluids with precision.

Power Generation: Control steam and cooling systems to optimize energy production.

Food and Beverage: Provide hygienic flow control in sensitive applications.

HVAC: Regulate heating and cooling systems for temperature control.

Reliability: Built to withstand harsh industrial environments, offering long-term performance.

Ease of Maintenance: Simple design ensures easy maintenance, reducing downtime and costs.

Energy Efficiency: Optimizes flow rates and reduces resistance, helping lower operational costs.

Pneumatic diaphragm single-seat control valves are essential for modern industrial automation systems. Their advanced design, precise control, and compliance with international standards make them suitable for a wide range of applications. Whether managing high-pressure pipelines or controlling sensitive fluids, these valves offer reliable and efficient flow management solutions, ensuring optimal system performance across industries.Know more about Google SEO Directory