Leading multicore flexible cable manufacturers offering durable, high-performance cables for power, automation, and control systems.

In modern times we need reliable power, and data transmission. This is not achievable without Multicore flexible cables. That is why Multicore flexible cables manufacturers plays vital role in development of nation’s economy. Multicore flexible cables manufacturers are now adapting to newer technologies and cutting edge tools and machineries that is capable of manufacturing high quality Multicore flexible cables that can be customized as per unique requirements.

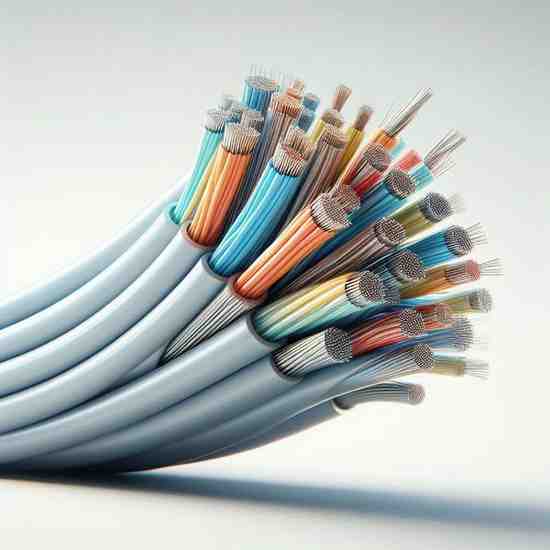

A multicore flexible cable has many conductors arranged and twisted together in a single outer jacket. Each core sends electrical current or signal independently. Its unique multicore quality can create a more compact installation with neat and tidy wiring configuration.

Moreover, the flexible outside jacket makes it easy to bend and not cause a break. Therefore, it is recommended for moving type applications like robotic arms, machine operations, and control panels. For its multiple applications and flexing capabilities while in use, it is not surprising that manufacturers of multicore flexible cables very much specialize in and meet industrial needs.

Most multicore cable manufacturers are focused on performance, durability, and electrical safety of every cable they manufacture unique to your specification. Each cable is flexible enough to handle continuous na refitted motion. They have excellent insulation for electrical safety in every environment. They are made with high-quality copper to ensure maximum conductivity. Suitable for the higher temperature range compatible with oil and chemically defined demanding industrial applications increase the longevity to the cable. These qualities will provide for consistent reliable performance across all applications.

Multicore flexible cables are used across multiple industries such as manufacturing, automation, telecommunications, and healthcare. In automation systems, multicore flexible cables connect the sensors, motors, and controllers. In a panel, multicore flexible cables distribute power safely. It is also used in IT and telecommunications for data transmission. In addition, multicore flexible cables connect construction tools and uniformly connect medical devices. As automation and digitalization increases across industries, multicore cable manufacturers in India will continue to grow in importance.

The production procedure associated with multicore flexible cables includes a number of stages that are tightly controlled to achieve quality and safety. The process begins with the drawing and annealing of copper (or aluminum) wires for better flexibility and conductivity of the final product. The wires are then stranded, insulated with premium materials, and laid together into an outer sheath. Lastly, the cables could be sheathed in PVC, or rubber prior to being tested for electrical and mechanical performance. The manufacturer always complies with rigorous ISO, CE, and RoHS standards to ensure consistency of quality in their production of flexible cables.

Selecting the ideal multicore flexible cable producer secures assurance in performance and value for money. Credible manufacturers produce quality products with options to modify core size, insulation, and sheath material. It’s worthwhile to consider the manufacturer’s credentials the manufacturer will be a source for sufficient industry experience, after-sale service, and your partner for a healthy manufacturing place, and it will help ultimately support efficiency, minimize downtime, and minimize repair costs.

India has emerged as a worldwide hub for cable production. With many local multicore flexible cable manufacturers leveraging advanced technology with a high degree of quality control, they are now successfully competing with global brands. Importantly, not only do local manufacturers provide products that rival performance, but they also do so at a competitive price point. Many cable manufacturers are exporting cables to Europe, the Middle East, and Africa. The rapid shipping of bulk orders has made them popular with industrial buyers worldwide. They are also focused on sustainability and environmentally-friendly production through green materials and more productive energy processes.

Top multicore flexible cable manufacturers are dedicated to conforming to the relevant and appropriate international and national standards for reliable performance. For instance, IS 694 is the governing standard for insulated wires and cables derived from PVC, while IEC standards govern the design, manufacture of, testing, and safety of cables. Furthermore, manufacturers are expected to adhere to RoHS laws in order to ensure that the hazardous material content does not exceed the limit specified. Manufacturers may also seek ISO certification to ensure quality control at any of the stages in the manufacturing process. The adherence to these standards assures the end user the multicore flexible cables will not exhibit under-performance or failure in any type of operating service.

Industry-specific factors result in the benefits of using multicore flexible cables. They allow for simple installation with their compact form-factor that promotes easy wiring and saves space. They are also insulated very well and the stranding pattern of their conductors makes them resistant to vibration, bending, and temperature changes. Their longevity also composes many cost savings through the necessary replacements being less frequent. Because of these factors, power, automation industries, and manufacturing rely on multicore cables in their respective mechanical and electrical applications.

Due to the rapid advancement of robotics and automation, there will be an increasing need for advanced flexible cables. Manufacturers of multicore cables are spending time and money on research & development to manufacture multicore cables with improved insulation, lighter weight and enhanced conductivity. Smart cables are also a growing market. Intelligent cables are designed to utilize built-in sensors to track performance information such as temperature, voltage and performance in real time. In general, multicore flexible cables are likely to continue to be very positive as technology evolves.

In conclusion, manufacturers of multicore flexible cables are a critical and integral player in supplying power to today’s industrial based and digital infrastructure. Their ingenuity, quality guarantees, and flexibility in their work are an important aspect of supplying the world with connectivity and automation. By collaborating with reliable and accredited manufacturers, companies can rest knowing their electrical functionality will continue to be safe, efficient, and endure for many years. Today’s advancement in technology, such multicore flexible cables will this will pave the way for the future of modern power, and communication networks to continue to expand.