Moisture meters are essential tools for professionals and hobbyists alike, helping to measure the moisture content in materials such as wood.

Accurate moisture readings are crucial for ensuring material quality, safety, and long-term durability. However, understanding meter accuracy is not always straightforward. In this article, we’ll explore what affects meter accuracy, how to ensure reliable readings, and why precision matters.

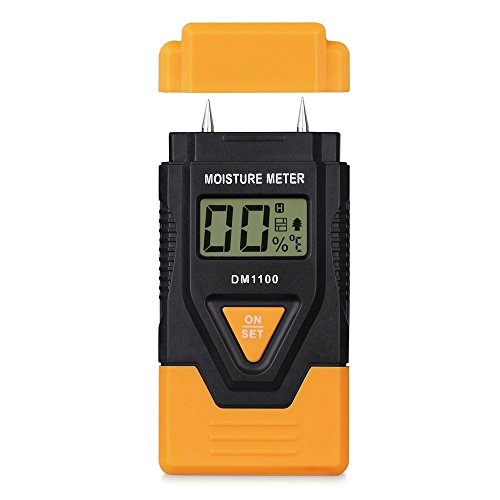

A moisture meter is a device that measures the water content in a material. There are two main types: pin-type and pinless (or non-invasive) meters.

Pin-type moisture meters use two metal probes that penetrate the material to measure electrical resistance. Since water conducts electricity, the resistance between the pins decreases as the moisture content increases. These meters are typically more accurate for spot readings and are widely used in woodworking, flooring, and drywall inspection.

Pinless meters use electromagnetic sensors to scan the surface of a material. They measure the moisture content without causing damage, making them ideal for finished surfaces or delicate materials. While convenient and non-destructive, pinless meters can be influenced by factors such as material density, temperature, and surface conditions.

Both types of meters provide readings in either percentage of moisture content or on a relative scale, depending on the material being measured. Accuracy varies between devices, so understanding the specifications and limitations of your meter is essential.

Several factors can impact the accuracy of moisture readings, and professionals need to account for these when making measurements.

Different materials conduct electricity and respond to electromagnetic signals in unique ways. For instance, hardwoods generally produce more consistent readings than softwoods due to their uniform density. Likewise, concrete with varying aggregate sizes can affect pinless meter readings. Using a meter calibrated for a specific material improves accuracy significantly.

Temperature affects the moisture content and the conductivity of materials. Cold surfaces may produce lower readings, while warm surfaces may register higher. Some advanced meters include temperature compensation features, which adjust readings based on the detected temperature.

Surface moisture, finishes, and coatings can distort readings. For example, water on the surface of a floor may register as high moisture content, even if the interior is dry. Pinless meters are particularly sensitive to surface irregularities, so cleaning the material and ensuring a smooth contact area can improve results.

Like any precision instrument, a meter must be properly calibrated and maintained. Over time, probes can corrode, sensors can drift, and batteries can weaken, all of which affect accuracy. Regular calibration using known reference materials helps ensure reliable measurements.

Accuracy can also be influenced by how the meter is used. Pin-type meters require firm, consistent pressure on the probes, and readings should be taken in multiple locations to account for material variability. Pinless meters should be placed flat and evenly on the surface, avoiding gaps that can interfere with the sensor.

Improving accuracy begins with selecting the right meter for your needs and applying proper measurement techniques. Here are some best practices:

Not all meters are suitable for every material. Wood meters, for example, may not give reliable readings on concrete or drywall. Using a material-specific meter increases reliability.

Follow the manufacturer’s guidelines for calibration. Some meters come with calibration blocks or reference charts to verify readings.

Take readings at several points across the material. This helps identify variations and provides a more accurate average moisture content.

If your meter has temperature compensation, enable it. Otherwise, consider adjusting readings based on known temperature effects.

If testing wood or drywall, ensure the surface is clean and dry. For pinless meters, press the device firmly to maintain consistent contact.

No meter is perfectly accurate under all conditions. Pin meters may overestimate moisture in highly conductive materials, while pinless meters may underreport moisture in dense or uneven surfaces. Recognizing these limitations allows you to interpret readings correctly.

Accurate moisture measurement is critical in several contexts:

Woodworking and Flooring: Excess moisture can lead to warping, cracking, and structural instability. Accurate readings prevent costly mistakes before installation.

Construction: Concrete and drywall must reach specific moisture levels before finishing or painting. Inaccurate measurements can result in mold growth, surface cracking, or adhesion failures.

Water Damage Restoration: Rapid detection of moisture is essential to prevent mold growth and structural damage. Misreading moisture levels can prolong restoration times and increase costs.

Agriculture and Landscaping: Soil moisture help optimize irrigation and prevent overwatering, which can harm plants and waste resources.

Inaccurate readings can have both financial and safety implications, underscoring the importance of choosing the right meter and using it properly.

Several misconceptions about meters can lead to misuse:

No meter provides perfectly exact readings. Even high-end devices offer approximations influenced by material type, temperature, and calibration.

While non-invasive and easy to use, pinless meters may not detect deep or localized moisture accurately. For some applications, a pin meter is necessary.

Moisture content can vary significantly across a material. Multiple readings are essential for an accurate assessment.

A poorly maintained meter can drift significantly, producing misleading readings that affect critical decisions.

Moisture meters are indispensable tools for anyone working with wood, construction materials, or soil. However, their effectiveness depends on understanding their limitations and the factors affecting accuracy. By selecting the right type of meter, calibrating regularly, taking multiple readings, and considering temperature and surface conditions, you can ensure reliable moisture measurements that prevent costly mistakes and structural problems.

Accuracy in moisture measurement is not just a technical detail; it’s a safeguard. Whether you’re installing a hardwood floor, assessing a water-damaged wall, or monitoring soil moisture, understanding how your meter works and what can affect its readings will save time, money, and headaches in the long run. Investing in a quality meter and proper measurement practices ensures confidence in every reading, letting you make informed, precise decisions every time.