Discover the meticulous process behind turning raw hemp into high-quality CBD, from extraction to quality control and sustainable practices.

CBD hemp processing involves converting raw hemp plants into high-quality CBD (cannabidiol) extracts through various sophisticated processes. This process is essential to meet the market demand for CBD products, which have become popular for their potential therapeutic effects. A CBD hemp processing company typically follows a multi-step approach to ensure that the final product meets both regulatory standards and customer expectations for purity, safety, and potency. Below is a breakdown of these key steps involved in processing CBD hemp.

The first stage in CBD production is the cultivation of hemp plants. These plants are grown specifically for their high CBD content and low levels of THC (tetrahydrocannabinol), the psychoactive component found in marijuana. Farmers must adhere to strict guidelines regarding plant quality and THC limits, as hemp crops need to stay within the legal threshold of 0.3% THC. The plants are usually harvested when they reach full maturity, as this is when CBD concentrations are at their highest.

Harvesting methods may vary, but the plants are typically cut and dried. Proper drying and curing are crucial to prevent mold growth and to preserve the cannabinoids and terpenes, compounds that contribute to the plant’s beneficial effects. Once dried, the hemp is stored in a controlled environment until it’s ready for processing. This preparation ensures the plants remain free of contaminants and retain the maximum level of active compounds.

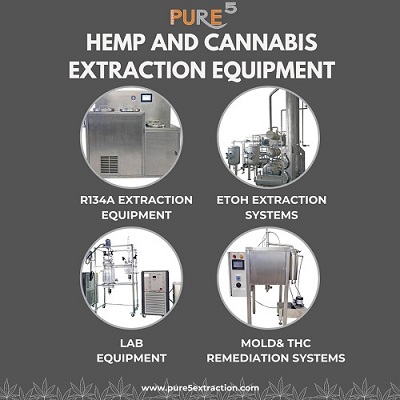

Extraction is a pivotal step in CBD processing. The goal of extraction is to separate the CBD and other beneficial cannabinoids from the plant material. There are several extraction methods, each with its pros and cons:

Each extraction method has its place in the industry, and the choice depends on the desired product quality and intended use.

After extraction, the product contains various compounds that may be undesirable, such as fats, lipids, and waxes. The winterization process removes these components by dissolving the extract in ethanol and freezing it. During this process, unwanted materials solidify and separate from the CBD-rich solution, leaving behind a purified extract. This step is essential to create a clean and potent CBD product that is smooth in texture and free of impurities.

Following winterization, distillation is performed to refine the CBD extract further. Distillation involves heating the extract to evaporate cannabinoids and then condensing them back into a purified liquid form. This step allows for the separation of different cannabinoids based on their boiling points, resulting in a higher concentration of CBD. Distillation is especially useful for producing full-spectrum, broad-spectrum, or isolate CBD products, each of which offers different cannabinoid profiles and potencies.

To produce CBD isolate, an additional purification process is required. CBD isolate is a crystalline form of pure CBD, containing no other cannabinoids, terpenes, or compounds. This process involves further refining the distilled CBD extract, often through chromatography, to achieve nearly 100% pure CBD. CBD isolate is commonly used in products where zero THC is a requirement, offering a precise and highly concentrated dose of CBD.

Quality control is a critical part of any CBD hemp processing company. Each batch of CBD extract undergoes rigorous testing to ensure it meets all safety and potency standards. Testing verifies the cannabinoid content, ensuring it matches the label claims and does not exceed THC limits. This stage also checks for potential contaminants like heavy metals, pesticides, mold, and residual solvents. Compliance with legal standards and adherence to best practices for consumer safety is paramount. Third-party lab tests are often performed for additional validation, providing transparency and trust for end-users.