Explore how Industry 4.0 is shaping the fourth industrial revolution through intelligent automation, IoT, and smart manufacturing.

In the grand timeline of human innovation, few milestones have reshaped industries as dramatically as the Industrial Revolutions: the first harnessed steam, the second electrified mass production, and the third computerized manufacturing. Today, a new wave of transformation is underway—Industry 4.0, a movement that is redefining how we produce, optimize, and innovate. The term might appear as just another buzzword in the tech playbook, but beneath it lies a seismic shift in industrial logic. Through the convergence of physical and digital systems, Industry 4.0 is not merely an upgrade; it embodies the principles and pace of a true revolution.

Industrial revolutions have always signified more than new tools—they’ve signaled foundational changes in how economies function and societies organize work. The First Industrial Revolution mechanized production using water and steam, liberating human effort from centuries of manual labor. The Second brought electricity and the assembly line, ushering in mass production and global supply chains. The Third—often referred to as the Digital Revolution—saw the rise of electronics and information technology, automating singular operations within rigid processes.

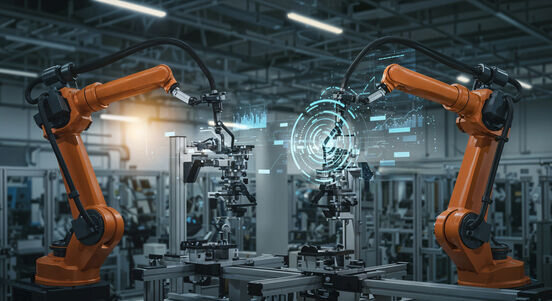

So, what precisely constitutes Industry 4.0? The concept revolves around embedding intelligence into every layer of the production process. Smart sensors collect and analyze data on the factory floor. Edge computing delivers actionable insights with minimal latency. Robotics and autonomous systems adjust in real-time based on predictive algorithms. Meanwhile, the Industrial Internet of Things (IIoT) ensures these components operate in seamless synchrony.

The significance of Industry 4.0 lies not in any one technology—be it AI, blockchain, or 5G—but in how these technologies coalesce into integrated, self-regulating systems. For instance, consider a production line where AI detects an anomaly, edge computing processes it on-site, and a robotic arm adapts its operation, all without human intervention. Such systems can reduce downtime, minimize waste, and elevate product quality. These aren’t isolated gains; they signal a broader transition where intelligence becomes the primary driver of value.

One of the hallmarks of the Industrial Revolution is its profound impact, not just on manufacturing, but on the very fabric of the economy and society. Industry 4.0 fits this criterion. It is already reshaping labor markets, global supply chains, and even geopolitics. Traditional job roles are being redefined as repetitive tasks are automated, and new roles emerge at the intersection of data science, system engineering, and human-machine collaboration.

From a business perspective, Industry 4.0 drives efficiency, agility, and resilience. Companies that adopt these frameworks can better weather disruptions, as demonstrated during the COVID-19 pandemic when digitalized operations outperformed manual systems. Predictive maintenance reduced unplanned downtimes. Real-time data enabled rapid pivots in production. Virtual commissioning allowed remote engineering. These capabilities aren’t peripheral—they are now central to competitive advantage.

Implementing Industry 4.0 is not an overnight endeavor. It requires a shift in both mindset and architecture. Companies must move from siloed digital projects to end-to-end integration. The Industry 4.0 technology stack spans from connected hardware and edge computing to centralized analytics and AI-driven decision engines. But successful adoption is not a technology-first game—it’s a strategy-first movement.

Leading enterprises don’t simply buy platforms; they build capability ecosystems. They invest in upskilling, embrace agile operations, and form cross-functional teams that align digital investments with business outcomes. Smart factories are designed not just for speed but for adaptability. Platforms like IBM Watson, for example, are helping organizations bridge OT and IT environments, enabling contextual decisions at the edge and strategic insights at the center.

Industry 4.0 is no longer a futuristic vision—it is a present-day reality reshaping the contours of manufacturing and beyond. As enterprises continue to integrate intelligent technologies across their operations, they are unlocking unprecedented efficiencies, resilience, and customer value. While the term may sound technical, the transformation it heralds is deeply human: about working smarter, building sustainably, and innovating with purpose.

By blending automation with cognition and connectivity with insight, Industry 4.0 brings the factory into the future—and in doing so, marks the undeniable arrival of the Fourth Industrial Revolution. Its relevance will only grow as businesses seek not just digital transformation, but intelligent reinvention. For those that embrace its full potential, the payoff isn’t just operational—it’s evolutionary.