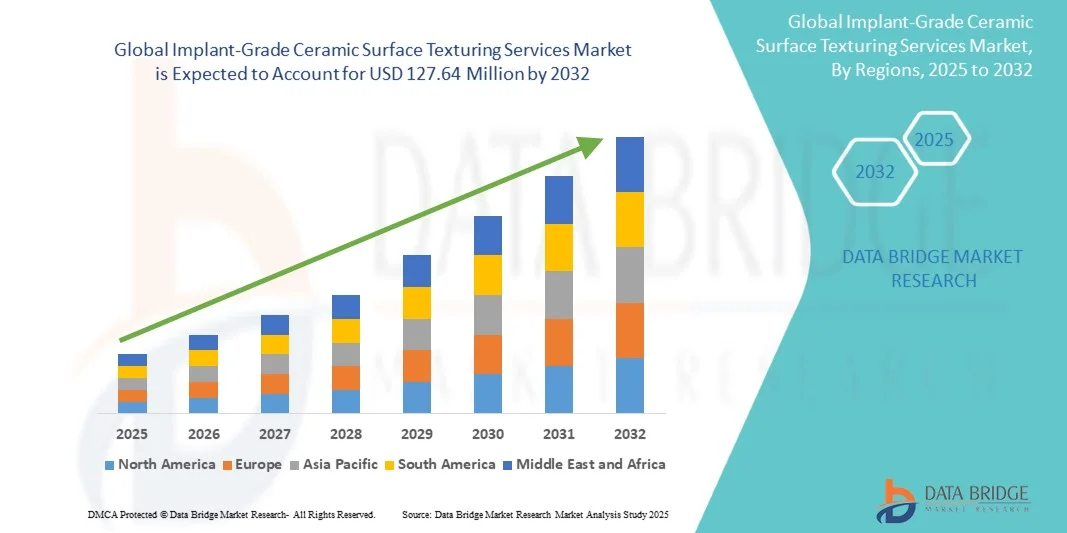

Implant-Grade Ceramic Surface Texturing Services market was valued at USD 45.00 Million in 2024 and is expected to reach USD 127.64 Million by 2032.

In the rapidly evolving world of biomedical engineering, implant materials and surface technologies play a crucial role in determining the success and longevity of medical implants. Among the various materials used, ceramics – particularly implant-grade ceramics such as zirconia (ZrO₂), alumina (Al₂O₃), and their composites – have emerged as highly desirable due to their biocompatibility, corrosion resistance, mechanical strength, and aesthetic appeal.

However, the natural bioinertness of ceramics can limit their integration with biological tissues. This is where ceramic surface texturing services come into play. Through precision-engineered surface modification techniques, implant-grade ceramic texturing enhances osseointegration, promotes cell adhesion, and improves mechanical interlocking with surrounding tissues – making it indispensable in today’s medical device manufacturing.

Implant-Grade Ceramic Surface Texturing Services refer to specialized processes that modify the surface of ceramic materials used in medical implants to enhance their biological performance and mechanical integration. These services use advanced techniques such as laser texturing, grit blasting, or chemical etching to create controlled micro- and nano-scale surface features, improving cell adhesion, osseointegration, and overall implant stability while maintaining the material’s biocompatibility and structural integrity.

Implant-grade ceramics are a specialized class of bioceramics engineered to meet stringent standards for purity, strength, and biocompatibility. Commonly used materials include:

These ceramics are widely used in dental implants, hip joints, spinal fusion devices, and bone scaffolds, where high load-bearing capacity and compatibility with biological environments are essential.

Yet, while ceramic materials are strong and stable, their smooth surfaces can hinder the biological attachment process. Surface texturing modifies the topography of the ceramic surface at micro- and nano-scales to promote better biological interaction.

The interface between an implant and biological tissue is critical for long-term success. For osseointegrated implants – such as those used in dental and orthopedic applications—surface roughness and texture directly influence:

As a result, surface texturing transforms bioinert ceramics into bioactive interfaces that facilitate stronger, faster bone bonding and tissue regeneration.

Modern implant-grade ceramic surface texturing services utilize a combination of mechanical, chemical, and laser-based techniques to achieve controlled surface modification without compromising material integrity.

Laser-based methods use high-precision beams to create micro- and nano-scale patterns on ceramic surfaces. Benefits include:

Femtosecond and nanosecond laser texturing are particularly effective for zirconia and alumina, producing features that enhance osseointegration and wettability.

This mechanical process involves bombarding the surface with abrasive particles such as alumina grit. It creates a uniform roughness, ideal for improving mechanical interlocking in orthopedic and dental implants. The challenge lies in maintaining cleanliness and avoiding residual contaminants.

Chemical etching with acids or alkalis can selectively modify the surface microstructure, increasing roughness and creating functional hydroxyl groups that improve cell adhesion. When combined with heat treatment, it can further enhance bioactivity.

Advanced plasma-assisted texturing can deposit nano-thin coatings or modify surface energy at the atomic level. Ion beam texturing allows for extreme precision, making it suitable for high-value implants requiring nanometer-scale modifications.

Hydrothermal or sol-gel processes can create bioactive nanostructures on ceramic surfaces, enabling superior cell interaction while maintaining the bulk strength of the material.

By increasing the surface area and modifying the surface energy, textured ceramics promote osteoblast activity, accelerating the integration of the implant with natural bone tissue.

Textured surfaces enhance friction and interlocking at the bone-implant interface, significantly reducing micromotion and the risk of implant failure.

Through controlled microtopography, manufacturers can design surfaces that influence specific cellular behaviors – encouraging bone cell attachment while minimizing bacterial colonization.

Improved bonding and reduced wear at the interface result in greater durability and longer implant lifespans – critical for orthopedic and dental applications.

In dental applications, zirconia implants with optimized surface textures not only achieve strong osseointegration but also maintain a natural, tooth-like color and translucency.

Implant-grade ceramic surface texturing services are in high demand across multiple industries, including:

Implant-grade ceramic surface texturing services must comply with strict international standards, such as:

Reliable service providers implement cleanroom processing, precision metrology, and full traceability to ensure the highest levels of safety and quality. Surface roughness, morphology, and chemistry are verified through advanced analytical tools such as SEM (Scanning Electron Microscopy), AFM (Atomic Force Microscopy), and XPS (X-ray Photoelectron Spectroscopy).

The next frontier in implant-grade ceramics lies in biofunctional surface engineering – combining texturing with bioactive coatings and nanotechnology. Researchers are developing multi-scale surface architectures that mimic the hierarchical structure of natural bone.

Emerging trends include:

These innovations will lead to implants that not only integrate seamlessly but also actively participate in tissue regeneration and healing.

Selecting the right ceramic surface texturing service provider is critical for implant manufacturers seeking to ensure consistent quality, compliance, and performance. When evaluating a partner, consider:

A collaborative approach – where surface scientists, engineers, and biomedical experts work together – ensures that each implant surface is optimized for both mechanical and biological performance.

According to Data Bridge Market Research, the size of the global implant-grade ceramic surface texturing services market was estimated at USD 45.00 million in 2024 and is projected to grow at a compound annual growth rate (CAGR) of 13.92% to reach USD 127.64 million by 2032.

Implant-grade ceramic surface texturing services are revolutionizing the biomedical device industry by bridging the gap between mechanical strength and biological functionality. Through advanced texturing techniques, manufacturers can transform bioinert ceramics into dynamic, bioactive materials that integrate naturally with human tissues.