Eccentric Plug Valves: Precision Flow Control for Industrial Applications

Eccentric Plug Valves: Precision Flow Control for Industrial Applications

Eccentric plug valves play a vital role in fluid control systems across a wide range of industries. Their distinctive design, featuring a cylindrical plug that rotates around an offset axis, allows for precise flow regulation and reliable shut-off. By minimizing friction and promoting unobstructed flow, these valves are an increasingly popular choice for applications demanding both durability and control. This article explores how eccentric plug valves function, their key benefits, and why they are favored in modern industrial operations.

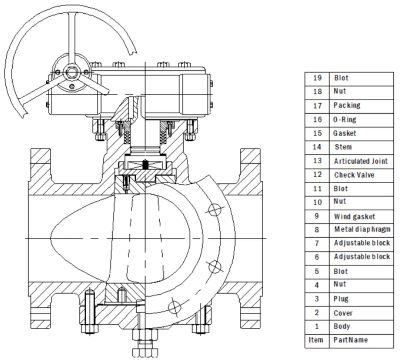

An eccentric plug valve is a quarter-turn rotary valve designed for regulating the flow of fluids. Its core component—a cylindrical plug mounted on an offset (eccentric) shaft—enables the plug to rotate in and out of the flow path with minimal resistance. This design provides tight shut-off performance, making these valves ideal for systems requiring reliable sealing and low-pressure drop.

Unlike linear motion valves, which open and close in a straight path, eccentric plug valves achieve closure via a 90-degree rotation. This quarter-turn operation simplifies actuation and enhances sealing, particularly under high-pressure or abrasive conditions. Common industries using eccentric plug valves include water and wastewater treatment, chemical processing, pulp and paper, and oil and gas.

The operation of an eccentric plug valve centers on the rotation of the plug and its interaction with the valve seat:

When actuated—either manually via a lever or automatically through a pneumatic or electric actuator—the plug rotates around its eccentric axis. As it turns, the plug moves into a raised seat, creating a mechanical advantage that ensures a firm, bubble-tight seal once closed.

The offset (eccentric) design ensures that the plug avoids contact with the valve seat until the final stage of closure. This “cam-like” motion minimizes friction, wear, and torque requirements, improving operational efficiency and extending the valve’s service life.

In the open position, the plug is completely clear of the flow path, allowing for streamlined, turbulence-free fluid movement. This characteristic is especially valuable in high-flow or particulate-laden applications where blockage or pressure drop must be minimized.

Reliable Shut-Off: The plug presses firmly into the seat at closure, delivering bubble-tight sealing even under varying pressures or in systems with suspended solids.

Low Maintenance: Reduced friction and wear translate to lower maintenance frequency and cost over time.

Excellent Flow Characteristics: The unobstructed flow path minimizes turbulence and energy loss.

Versatile Applications: Suitable for handling slurries, corrosive chemicals, and wastewater, thanks to options for lined or metal-seated variants.

Durability: The eccentric movement minimizes seat and plug erosion, contributing to a longer operational lifespan.

Eccentric plug valves offer a superior blend of precision, durability, and operational efficiency. Their quarter-turn operation, combined with a friction-minimizing design, ensures reliable performance in even the most demanding environments. Whether used for regulating aggressive chemicals, abrasive slurries, or clean water, these valves provide long-term value through reliable sealing, low maintenance, and efficient flow control.

As industrial systems continue to evolve and demand higher performance from their components, eccentric plug valves stand out as a reliable and effective solution for modern fluid handling challenges.Know more about Google SEO Directory