Electric Ball Valves: A Comprehensive Guide to Operation, Applications, and Maintenance

Introduction

We are a leading control valve manufacturer in China, delivering high-quality valves and control actuators customized to meet a wide range of industrial requirements.

Electric ball valves play a critical role in modern fluid control systems across industrial and commercial sectors. By combining mechanical efficiency with electrical automation, these valves offer fast, precise, and reliable control over the flow of liquids and gases. Unlike manual valves, electric ball valves can be operated remotely, making them ideal for environments where safety, speed, or convenience is a priority.

This article outlines how electric ball valves work, where they are commonly used, and how to maintain them. It also highlights the importance of power-failure reset mechanisms to ensure safe operation during outages.

What Is an Electric Ball Valve?

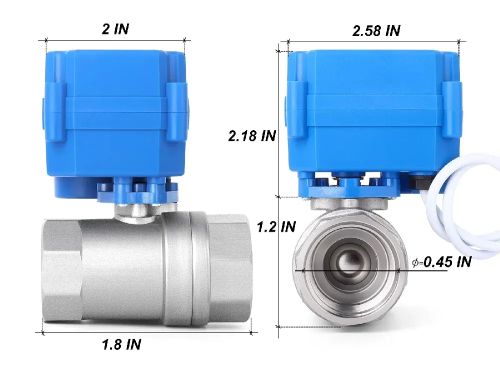

An electric ball valve is an automated valve that uses an electric actuator to rotate a spherical ball with a hole through its center. As the actuator turns the ball 90°, it aligns or misaligns the bore with the pipeline, allowing or stopping flow. These valves can fully open, close, or partially open depending on the control signal.

Key Features

Quick Actuation: Opens or closes in seconds, suitable for time-sensitive systems

Accurate Flow Control: Capable of partial opening for modulated flow

Durable Construction: Built to endure high pressures and harsh environments

Automation-Friendly: Compatible with PLCs, SCADA systems, and IoT platforms

How It Works

When an electric signal is received, the actuator drives the valve stem, rotating the ball to the required position. Positioners ensure the ball aligns precisely based on control input. This eliminates the need for manual operation and allows integration into fully automated systems.

Typical Applications

Electric ball valves are widely used in:

Industrial Systems: For fluid handling in chemical plants, water treatment, and oil & gas pipelines

HVAC: To control heating/cooling flows and manage energy efficiency

Food & Beverage: For hygienic, accurate batching and flow control

Power Generation: In steam lines and coolant flow regulation

Safety Systems: As emergency shut-off valves in fire protection and gas leak prevention

Troubleshooting Common Issues

Despite their reliability, problems may occur:

Slow or erratic operation: Often due to low voltage—check power supply

Sticking or friction: Caused by debris or lack of lubrication—clean and service valve

Signal interference: Can result from nearby electromagnetic equipment—add shielding or relocate

Wear and tear: Worn seals or components should be inspected and replaced as needed

Maintenance Best Practices

Regular preventive maintenance helps extend service life:

Inspect for leaks or corrosion

Ensure proper installation and secure wiring

Use upstream filters like Y-strainers to prevent clogging

Schedule lubrication and test valve responsiveness periodically

Power-Failure Reset Systems

To maintain safety during power loss, many electric ball valves include automatic closure mechanisms:

Spring Return: Uses stored mechanical energy to force the valve shut

Battery/Capacitor Backup: Maintains control to close the valve smoothly after power loss

These features are essential in critical systems—like chemical processing or gas lines—where uncontrolled flow can pose serious risks.

Conclusion

Electric ball valves offer smart, safe, and efficient fluid control across a wide range of applications. Their ability to integrate into automated systems, combined with fast actuation and low maintenance, makes them a top choice in modern infrastructure. With proper selection, maintenance, and the use of safety features like power-failure reset systems, these valves provide long-term value and reliability.Know more about Google SEO Directory