Discover CNC milling services, CNC turning services, and the different types of rivets with their uses to achieve precision,

In modern manufacturing, precision and reliability are non-negotiable. Companies across industries—from aerospace to automotive—rely on advanced machining methods like CNC milling services and CNC turning services to produce high-quality parts. At the same time, joining and fastening components often require knowledge of different types of rivets, as rivets remain one of the strongest and most reliable mechanical fasteners.

This blog explores how CNC machining supports the production of riveted components and provides an overview of the most common rivet types and their uses.

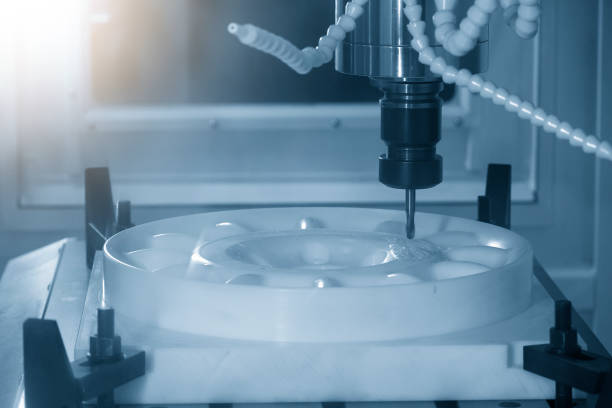

CNC milling services are among the most widely used manufacturing processes today. CNC milling involves rotating cutting tools that remove material from a workpiece to create precise shapes and dimensions. Using computer-controlled machinery, manufacturers can achieve tight tolerances, smooth finishes, and complex geometries that are impossible with manual machining.

High precision and repeatability for consistent part quality.

Flexibility to create prototypes, small batches, or large-scale production runs.

Versatility in machining metals, plastics, and composites.

Reduced lead times thanks to automation and advanced software integration.

These advantages make CNC milling an ideal solution for industries requiring accuracy and durability, such as aerospace, electronics, and automotive manufacturing.

Beyond machining, fastening is a critical part of the production process. Rivets have been used for centuries as a strong, reliable method of permanently joining two or more materials together. Unlike bolts and screws, rivets don’t require threads, making them ideal for high-strength, vibration-resistant applications.

When sourcing or designing parts, engineers must understand the different types of rivets available and how they’re used. This ensures stronger assemblies and better overall performance.

Here’s an overview of the most common rivet types:

Description: The oldest and most reliable type, made from a solid shaft with a head. Installed using a hammer or rivet gun.

Uses: Aerospace, automotive, and heavy machinery where strength and durability are critical.

Description: Installed from one side of the workpiece, making them ideal for areas with limited access.

Uses: Electronics, aircraft interiors, and consumer goods.

Description: Feature a hollow shaft, making installation easier and reducing weight.

Uses: Leather goods, luggage, and light sheet metal applications.

Description: Have split legs that spread apart during installation for a secure grip.

Uses: Soft materials like wood, plastic, or leather.

Description: Installed by driving a mandrel into the rivet body, expanding it in place.

Uses: Applications requiring quick assembly with minimal tools.

Description: Sit flush with the material surface, reducing drag and creating a smooth finish.

Uses: Aerospace and automotive industries for aerodynamic and aesthetic purposes.

Description: Do not require pre-drilled holes, as they pierce and fasten materials in one step.

Uses: Automotive assembly, particularly for aluminum and lightweight materials.

When selecting rivets, manufacturers must consider factors such as:

Material strength and thickness of the components.

Accessibility (one-sided or two-sided installation).

Environmental conditions (corrosion resistance, temperature tolerance).

Aesthetic requirements, especially for visible surfaces.

Understanding the types of rivets and uses ensures that assemblies are not only functional but also long-lasting and efficient.

Interestingly, many rivets themselves are manufactured using CNC milling services and CNC turning services. CNC machining ensures rivets are produced with precise dimensions, uniform strength, and excellent surface finishes. This guarantees reliable performance, especially in industries where safety is critical.

For example:

Solid rivets used in aerospace require extremely tight tolerances, which CNC machining can deliver.

Blind rivets often feature small, intricate components that benefit from the accuracy of CNC milling.

Drive rivets and flush rivets are commonly turned on CNC lathes for smooth, consistent shapes.

Manufacturing excellence requires a combination of precision machining and reliable fastening methods. CNC milling services and CNC turning services play a vital role in producing both finished parts and the rivets used to assemble them. By understanding the different types of rivets, their characteristics, and their applications, manufacturers can select the best fastening solution for their projects.

When combined with the accuracy of CNC machining, riveted assemblies deliver the strength, durability, and reliability needed in industries where performance matters most.