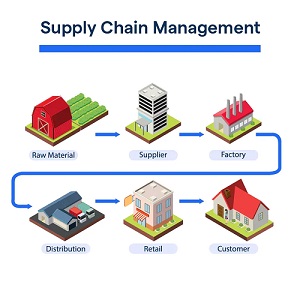

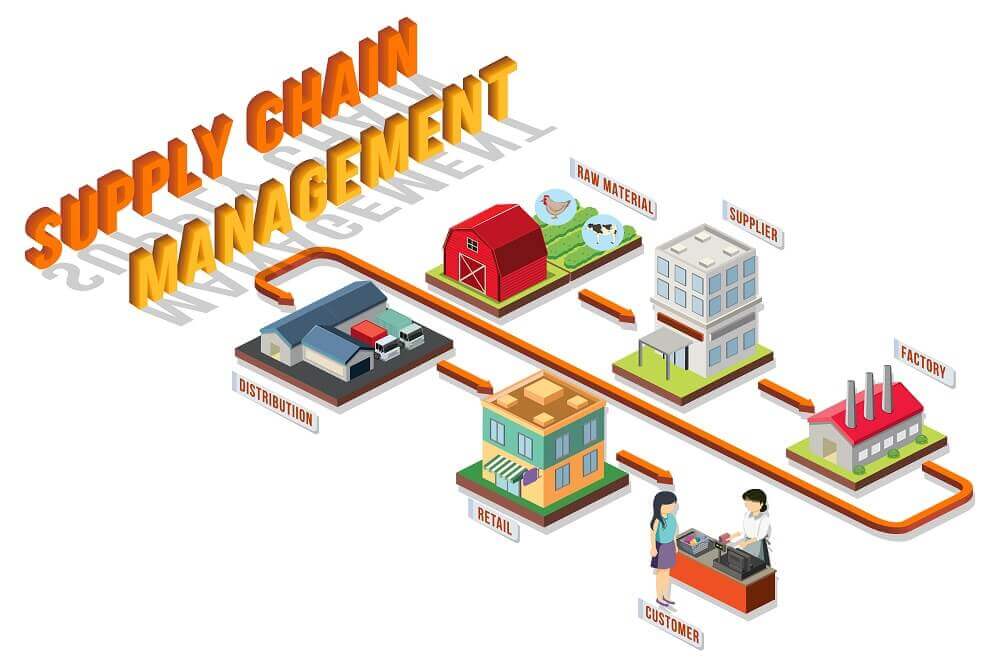

Data-Driven Decision Making in Supply Chain Management

The shift toward data-driven decision-making is revolutionizing Supply Chain Management.

© 2024 Crivva - Business Promotion. All rights reserved.