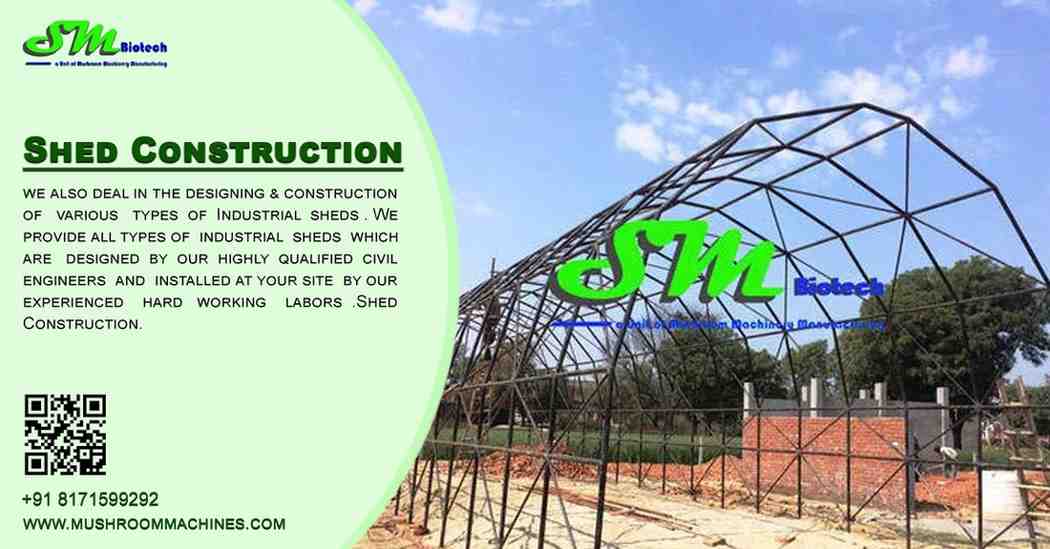

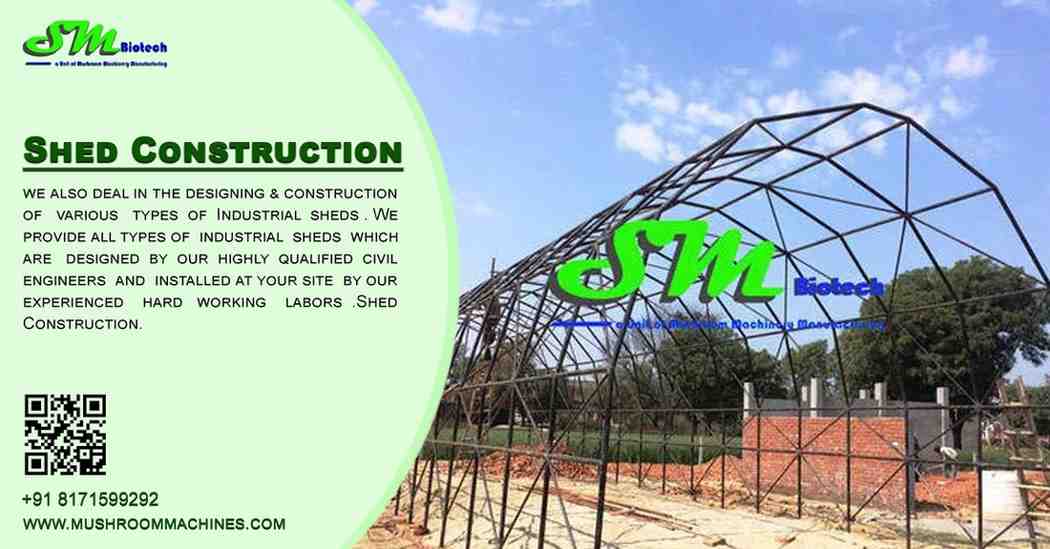

Shed Construction for Profitable Mushroom Farming

MushroomMachines help you build the ideal environment for your mushrooms to thrive.

© 2024 Crivva - Business Promotion. All rights reserved.