Eccentric Plug Control Valves: Precision and Durability in Industrial Flow Control

Eccentric Plug Control Valves: Precision and Durability in Industrial Flow Control

Introduction

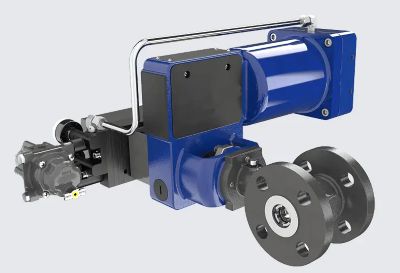

China Control valves play a crucial role in industrial fluid systems by precisely regulating flow, pressure, and direction. Among the diverse types available, the eccentric plug control valve stands out due to its unique design and exceptional performance with challenging media such as slurries, viscous liquids, and abrasive fluids. This article explores the working principle, key features, applications, and advantages of eccentric plug control valves in modern industrial processes.

What Is an Eccentric Plug Control Valve?

An eccentric plug control valve is a quarter-turn rotary valve designed for accurate flow regulation. Unlike traditional plug valves that have a centered plug, the eccentric plug valve features an off-center plug. This offset design reduces friction and wear during operation, improving valve longevity and reliability.

Key Design Characteristics:

Eccentric Plug: Off-center plug lifts away from the seat as it rotates, minimizing contact and wear.

Robust Construction: Built from durable materials such as stainless steel or hardened alloys to withstand harsh environments.

Tight Shutoff: Provides secure sealing to prevent leakage.

Self-Cleaning Action: Rotational movement prevents debris buildup on the seat, maintaining performance.

These features make eccentric plug valves especially suited for demanding industries like oil and gas, chemical processing, power generation, and water treatment.

Working Principle

The valve’s operation ensures minimal friction and precise flow control through a simple yet effective mechanism:

Closed Position: The eccentric plug is pressed firmly against the seat, creating a leak-proof seal. The offset design distributes sealing forces evenly.

Opening Process: A quarter-turn rotation lifts the plug from the seat immediately, reducing friction and wear.

Flow Control: Partial rotations allow fine flow adjustments, while the straight-through flow path minimizes turbulence and pressure loss.

Self-Cleaning: The rotating plug prevents sediment or particle buildup, enhancing reliability especially in abrasive or slurry media.

Key Features and Advantages

| Feature | Description |

|---|---|

| Tight Shutoff | Hard-seal variants meet ANSI Class IV, soft-seal versions achieve Class VI zero leakage. |

| Low Operating Torque | Eccentric design reduces friction, requiring less force to operate. |

| Self-Cleaning Action | Prevents clogging in slurry and high-solid-content fluids. |

| Extended Seat Life | Inlet flow path design protects seat from erosion. |

| Split Spool Design | Allows customized material selection for corrosion resistance. |

| One-Piece Stem Design | Provides rigidity and precise valve positioning. |

| Anti-Fly-Out Stem | Prevents stem ejection under high pressure for safety. |

| Easy Maintenance | Simple construction enables quick disassembly and servicing. |

Applications

Eccentric plug control valves are widely used in:

Oil & Gas: Handling crude oil, refined products, and natural gas under high pressure and corrosive conditions.

Chemical Processing: Managing acids, alkalis, and abrasive chemicals with corrosion-resistant materials.

Power Generation: Controlling steam, boiler feedwater, and cooling fluids in high-temperature systems.

Water & Wastewater: Regulating sludge, slurry, and treated water flows with self-cleaning features to prevent clogging.

Performance Advantages Over Conventional Valves

Superior Flow Capacity: Straight-through design reduces turbulence and pressure drops for efficient flow.

Enhanced Durability: Hardened materials and extended seats resist erosion and wear.

Reduced Maintenance: Self-cleaning and simple design cut downtime and service costs.

Safety & Reliability: Anti-fly-out stems and leak-proof seals meet stringent industry standards.

Choosing the Right Valve

When selecting an eccentric plug control valve, consider:

Material Compatibility: Match valve materials to chemical and abrasive media.

Pressure & Temperature Ratings: Ensure valve ratings meet process demands.

Valve Size & Flow Coefficient (Cv): Proper sizing avoids pressure loss and achieves efficient control.

Actuation Method: Choose manual or automated actuators based on operational needs.

Sealing Requirements: Soft seals for tight shutoff, metal seats for high temperature or abrasion.

Maintenance Ease: Opt for valves with easy access and self-cleaning features.

Conclusion

Eccentric plug control valves combine a unique off-center design with robust construction to deliver reliable, low-maintenance, and precise fluid control. Their superior sealing, durability, and self-cleaning action make them indispensable across oil & gas, chemical, power, and water treatment industries. Proper valve selection ensures optimal system performance, reduced downtime, and long-term cost savings.Know more about Google SEO Directory

© 2024 Crivva - Business Promotion. All rights reserved.