When it comes to installing a steel roof, the strength of the structure doesn’t just depend on the steel beams or panels

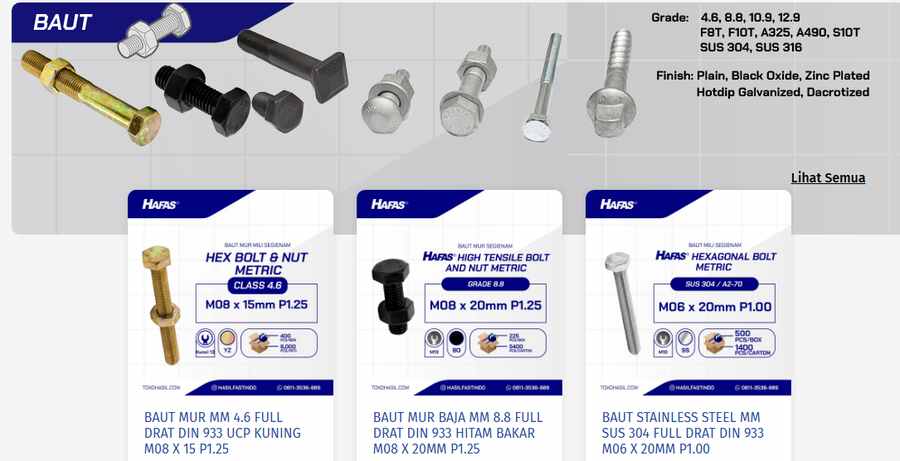

When it comes to installing a steel roof, the strength of the structure doesn’t just depend on the steel beams or panels—it also relies heavily on the fasteners that hold everything together. Baut Mur/ Bolts and nuts play a critical role in the integrity and safety of a steel roofing system. Choosing the right type, size, and material of bolts and nuts is essential for ensuring a durable, weather-resistant, and structurally sound roof.

In steel roofing installations, fasteners like bolts and nuts are used to connect steel components such as purlins, rafters, and panels. These connections must be able to withstand high loads, vibrations, temperature changes, and environmental exposure. Poor-quality or incorrectly chosen bolts can lead to loose connections, leaks, corrosion, and even structural failure.

Hex bolts rank as one of the most frequently utilized fasteners in metal roofing applications. They are strong, easy to install with standard tools, and available in various grades of steel. Paired with hex nuts, they provide a secure and stable connection between steel members.

Carriage bolts, with their smooth rounded heads and square necks, are useful when a flush finish is needed on one side. They are typically used in conjunction with steel plates or brackets.

U-bolts serve to fasten cylindrical items, like pipes or rods, to metal frameworks. In roofing, they may be used to attach curved steel elements or for supporting mechanical components.

While not technically bolts and nuts, self-drilling screws are frequently used in modern steel roofing to attach metal panels directly to framing. These screws often come with integrated washers to ensure a watertight seal.

Fasteners for outdoor roofing must be corrosion-resistant. Galvanized or stainless steel bolts and nuts are highly recommended. For coastal or industrial environments, higher-grade stainless steel (like 316) offers better protection against rust and corrosion.

The bolts must meet the structural load requirements of the roofing system. Engineers typically calculate the shear and tensile strength needed for each connection point. Using under-rated fasteners can lead to joint failure over time.

UV radiation, rain, and temperature changes can affect fasteners. Weather-resistant coatings and rubber washers are often used to prevent water ingress and maintain tight seals.

Bolts and nuts that are compatible with standard installation tools (like wrenches or impact drivers) help speed up the construction process and reduce labor costs.

In large commercial or industrial roofing systems, fasteners that are easy to inspect and tighten are preferred. Over time, regular maintenance checks ensure that all bolts remain secure.

Mixing Metals: Using bolts and nuts made from different metals can cause galvanic corrosion. Always pair fasteners made from the same or compatible materials.

Over-tightening: Applying too much torque can strip threads or deform steel components. Torque specifications should always be followed.

Skipping Washers: Washers distribute the load and prevent damage to the surfaces. They also help seal out moisture when used with roofing panels.

Bolts and nuts may seem like small parts in a steel roofing system, but their role is absolutely vital. Choosing the right type, grade, and size ensures a secure and lasting installation. Whether you are building a warehouse, factory, or commercial structure, investing in high-quality fasteners is key to long-term performance and safety. Consult with structural engineers and follow manufacturer guidelines to get the most out of your steel roofing system.

© 2024 Crivva - Business Promotion. All rights reserved.